You might be wondering how the textile market will evolve in the coming years. With a growing emphasis on sustainability, you'll see a rise in bio-based fibers and waterless dyeing techniques. But that's just the start. Imagine integrating AI and blockchain into production processes, or the potential of smart textiles that can interact with the environment. As these technological advancements unfold, the need for ethical practices and global market integration will become even more vital. So, how will these trends shape the future landscape of textiles, and what challenges might arise?

Table of Contents

Key Takeaways

- Increased use of sustainable materials like organic cotton and recycled polyester will dominate the textile market.

- Technological advancements, such as AI and blockchain, will enhance supply chain transparency and efficiency.

- Smart textiles with health monitoring and energy generation capabilities will become more prevalent.

- Ethical manufacturing practices will be crucial in elevating brand reputation and consumer trust.

- Globalization will continue with emerging regions like Vietnam and Bangladesh playing key roles in production.

Sustainable Materials

In the coming years, you'll see a significant shift towards sustainable materials in the textile market. This change is driven by the growing demand for eco-friendly products and the pressing need to reduce environmental impact. As someone who desires mastery in this field, you'll want to stay ahead by understanding and adopting these innovations.

Bio based fibers are at the forefront of this transformation. Derived from renewable resources like corn, soy, and bamboo, these fibers offer a sustainable alternative to traditional materials. They not only reduce dependency on petroleum-based products but also minimize carbon footprints. Mastering the use of bio based fibers will position you as a leader in sustainable fashion.

Textile recycling is another vital aspect you can't overlook. The process involves converting old or discarded fabrics into new, usable materials, thereby reducing waste and conserving resources. By integrating textile recycling into your production processes, you'll contribute to a circular economy and enhance your brand's sustainability credentials.

Embracing these practices won't only meet the evolving consumer preferences but also set new industry standards.

Smart Textiles

You're about to see a revolution in textiles with smart fabrics that can monitor your health and even generate energy.

Imagine wearing clothes that track your essential signs or charge your devices.

These innovations could soon become part of your everyday wardrobe.

Wearable Health Monitoring

Smart textiles are revolutionizing healthcare by providing real-time, wearable health monitoring solutions. Imagine a world where your clothing can track your essential signs, alert you to health anomalies, and even notify your healthcare provider remotely. That world isn't far off. With advanced sensors woven into fabrics, you get seamless remote monitoring and health tracking capabilities integrated into everyday wear.

Wearable technology in textiles goes beyond basic fitness monitoring. It offers detailed insights into your heart rate, respiratory patterns, and even stress levels. The fabrics can measure biometric data continuously, providing you with crucial information to make informed health decisions. If you're managing a chronic condition, this constant stream of data can be a lifesaver, allowing for early intervention and personalized care.

The convenience of wearable health monitoring means you're no longer tethered to bulky devices or frequent doctor visits. Instead, your smart clothing does the heavy lifting, ensuring you stay informed and healthy. As these innovations become more mainstream, you'll see a significant shift in how health data is collected, analyzed, and utilized, ultimately leading to more proactive and preventive healthcare strategies.

Energy-Harvesting Fabrics

Imagine your clothing not only monitoring your health but also generating its own power through energy-harvesting fabrics. This isn't science fiction; it's the next frontier in textile innovation.

By integrating tiny photovoltaic cells and piezoelectric fibers, your clothing can convert solar energy and mechanical movement into electrical power. These energy efficient textiles promise to revolutionize how we approach both fashion and functionality.

Energy-harvesting fabrics are more than just a novelty; they're performance enhancing fabrics that can power wearable devices, extending battery life and reducing the need for frequent charging. Whether you're an athlete tracking your performance or a professional on the go, these textiles offer practical advantages that go beyond aesthetics.

Moreover, renewable energy textiles align perfectly with sustainable fashion trends. By harnessing renewable sources, such as the sun or kinetic energy, these fabrics minimize environmental impact while offering high-tech benefits. This not only supports sustainability but also paves the way for smarter, greener solutions in the fashion industry.

Embrace the future of fashion where your clothing isn't just a statement but a powerhouse of technology and sustainability. Energy-harvesting fabrics are set to redefine what you wear and how you wear it.

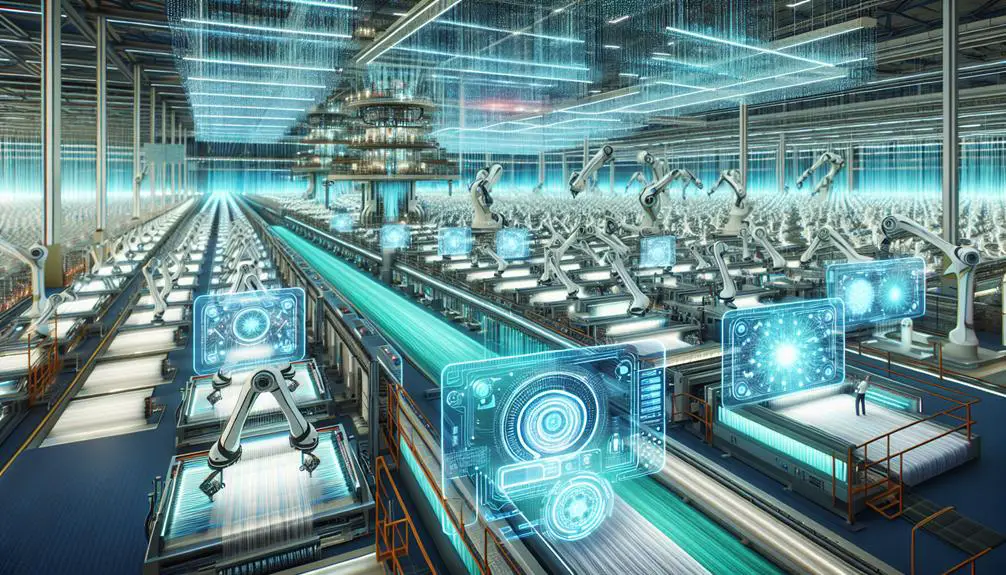

Artificial Intelligence

In the textile market, artificial intelligence is transforming everything from design processes to supply chain management. You're now able to harness AI powered design tools that can revolutionize your creative workflows. These tools analyze vast datasets, enabling you to predict trends and customer preferences with remarkable precision. Imagine designing a new collection that's not just stylish but also accurately aligned with market demands.

Predictive analytics are another game-changer. By leveraging AI, you can forecast demand more precisely and optimize inventory levels, reducing waste and enhancing profitability. You'll know which materials to stock up on, and when to produce specific items, all thanks to data-driven insights. This level of precision guarantees you stay ahead of the competition.

AI doesn't stop at design and inventory. It's also streamlining supply chain management. Automated systems can monitor and adjust production schedules in real-time, guaranteeing timely delivery and minimizing disruptions. By integrating AI into your operations, you'll achieve unmatched efficiency and responsiveness.

Incorporating artificial intelligence into your textile business isn't just a trend; it's a strategic move that positions you for sustained success in an increasingly competitive market. Embrace these advancements, and you'll master the future of textiles.

Blockchain Integration

Beyond its origins in cryptocurrency, blockchain technology is revolutionizing the textile industry by enhancing transparency, traceability, and security across the supply chain. You're no longer limited to relying on fragmented information or opaque processes.

Blockchain's immutable ledger records every transaction, ensuring you have a clear, reliable history of each textile product.

Imagine being able to verify the journey of a fabric from raw material to finished garment. With blockchain, each step in the supply chain is documented, giving you thorough visibility. This level of transparency and traceability means you can confidently assure stakeholders and consumers about the authenticity and origin of your products.

Moreover, blockchain minimizes risks associated with counterfeit goods. By embedding unique identifiers within the blockchain, you can authenticate products easily, protecting your brand and maintaining consumer trust. Additionally, smart contracts streamline transactions and reduce inefficiencies, saving you time and money.

Integrating blockchain into your operations isn't just a trend—it's a strategic move towards a more accountable and efficient supply chain. By leveraging this technology, you're not only advancing your business but also setting a new standard for industry best practices.

Embrace blockchain and lead the future of textiles with confidence.

Eco-Friendly Production

You're about to see major shifts in textile production with a focus on eco-friendly methods.

Companies are adopting sustainable material innovations, waterless dyeing techniques, and circular economy models.

These changes aim to reduce environmental impact and promote a more sustainable future.

Sustainable Material Innovations

How are groundbreaking sustainable materials shaping the future of eco-friendly textile production?

You're witnessing a revolution in sustainable fashion, driven by the innovation of eco-friendly textiles. Materials like organic cotton, bamboo, and recycled polyester are becoming the norm rather than the exception. These materials not only reduce environmental impact but also enhance the quality and longevity of the garments you wear.

By choosing eco-friendly textiles, you're supporting a system that prioritizes the well-being of our planet. For instance, organic cotton requires notably less water and eliminates harmful pesticides, making it a healthier option for both the environment and the farmers.

Bamboo, known for its rapid growth, is naturally anti-bacterial and biodegradable, offering a versatile alternative for various textile applications.

Recycled polyester, made from discarded plastic bottles, diminishes waste and energy consumption in production. When you opt for garments made from these materials, you're contributing to a circular economy that values sustainability over disposability.

The textile market is rapidly evolving, and your choices are pivotal in steering it towards a greener future. Embrace these innovations and become a catalyst for change in sustainable fashion.

Waterless Dyeing Techniques

Waterless dyeing techniques are revolutionizing textile production by reducing water usage and minimizing pollution. Embracing these methods, you can cut down significantly on one of the industry's most pressing environmental concerns. Instead of relying on vast amounts of water to dye fabrics, innovative technologies like supercritical CO2 dyeing are utilized. These methods not only save water but also eliminate the need for harmful chemicals, leading to zero waste processes.

By adopting waterless dyeing, you're contributing to resource conservation, a critical aspect of sustainable solutions. This approach uses up to 50% less energy and reduces carbon emissions, directly benefiting the environment. You're not just improving your eco-footprint; you're setting a new standard for responsible production in the textile industry.

Moreover, waterless dyeing enhances fabric quality and color consistency, ensuring your products meet high standards of excellence. This technique also cuts down on production time, making your operations more efficient.

As you master these sustainable solutions, you position yourself at the forefront of a growing movement towards eco-friendly manufacturing. Integrating these cutting-edge technologies reflects a commitment to innovation and sustainability, ultimately giving you a competitive edge in the market.

Circular Economy Models

Embracing circular economy models in textile production allows you to reduce waste and resource consumption to a large extent. By focusing on sustainability, you can innovate in textile recycling and drive significant environmental benefits. A circular economy minimizes waste through thoughtful design and resource efficiency, ensuring that products are made to last and materials are reused.

Here are three actionable steps to integrate circular economy principles into your textile business:

- Adopt Textile Recycling Innovations: Implement cutting-edge technologies to recycle fibers from old garments. This not only decreases landfill waste but also reduces the need for virgin materials.

- Design for Durability and Reusability: Create products with longevity in mind. Use modular designs that allow for easy repair and upgrading, extending the product's lifecycle and reducing the frequency of replacement.

- Close the Loop with Take-Back Programs: Encourage consumers to return used textiles by offering incentives. These items can then be processed and remanufactured into new products, fostering a sustainable loop.

Ethical Manufacturing

Ethical manufacturing practices are rapidly transforming the textile industry by prioritizing sustainability and fair labor conditions. You can see this shift through initiatives that focus on worker empowerment and fair trade practices. By adopting these principles, companies guarantee that laborers receive fair wages, safe working environments, and opportunities for growth. This not only enhances the quality of life for workers but also elevates the reputation of the brands involved.

When you support ethical manufacturing, you contribute to a system that values human rights and environmental stewardship. The following table highlights key differences between traditional and ethical manufacturing practices:

| Aspect | Traditional Practices | Ethical Practices |

|---|---|---|

| Labor Conditions | Often poor, unsafe | Safe, fair, and empowering |

| Environmental Impact | High pollution, waste | Low impact, sustainable methods |

| Worker Compensation | Low wages, exploitation | Fair wages, benefits |

| Community Impact | Minimal, often negative | Positive, community-focused |

Circular Economy

As ethical manufacturing gains momentum, the textile industry is also embracing a circular economy to minimize waste and maximize resource efficiency. You can play an important role in driving this transformation by focusing on resource recycling and waste reduction. These strategies not only conserve materials but also reduce the environmental footprint of textile production.

Here are three key approaches you can adopt:

- Resource Recycling: Implement systems that allow for the recovery and reuse of materials from old textiles. By integrating advanced sorting and recycling technologies, you can make sure that fabrics are repurposed rather than discarded, contributing to significant waste reduction.

- Upcycling Initiatives: Encourage innovative design practices that transform waste materials into new, high-quality products. Upcycling not only adds value to discarded textiles but also fosters creativity and sustainability within your operations.

- Closed Loop Systems: Develop processes where materials are continuously cycled back into production. This approach minimizes waste and reliance on virgin resources, creating a sustainable supply chain that aligns with circular economy principles.

Digital Printing

Digital printing is revolutionizing the textile industry by offering unparalleled flexibility and efficiency in fabric design and production. You're now able to achieve intricate patterns and vibrant colors with precision, thanks to advances in textile technology. This shift is setting new digital textile trends, allowing you to keep ahead of the curve by quickly adapting to market demands.

Innovation in printing has made digital fabric printing a game-changer. You can eliminate many of the time-consuming steps traditionally involved in textile production. With digital printing, you can print directly onto fabrics, reducing waste and streamlining the process. This method also allows for shorter production runs, making it possible to experiment with new designs without committing to large quantities.

Furthermore, digital fabric printing opens up endless design possibilities. You can create complex, multi-colored prints with ease, something that would be difficult with conventional methods. The precision offered by digital textile technology ensures that every detail of your design is accurately reproduced, giving you a competitive edge.

Customization Trends

You can expect a surge in personalized fabric designs, making it easier to cater to unique tastes and preferences.

On-demand manufacturing services will further streamline this trend, allowing for quick and efficient production.

These developments are set to transform how you interact with textile products.

Personalized Fabric Designs

The rise of personalized fabric designs is reshaping the textile industry, offering consumers unique and customized products. With innovations like custom design and digital printing, you can now create fabrics that reflect your distinct style and vision.

This shift towards personalization means you no longer have to settle for mass-produced patterns that don't quite capture your individuality.

Personalized fashion is at the forefront of textile innovation, allowing you to design garments that are truly one-of-a-kind. This trend is driven by several factors:

- Digital Printing: This technology enables precise and intricate designs to be printed directly onto fabric, offering unmatched customization options.

- Consumer Demand: There's a growing desire for unique clothing that stands out, and personalized fabric designs meet this need perfectly.

- Technological Advancements: Innovations in textile production allow for more efficient and cost-effective customization, making personalized fashion accessible to a wider audience.

On-Demand Manufacturing Services

In an age where instant gratification is highly valued, on-demand manufacturing services are revolutionizing the textile market by enabling rapid production of custom-designed fabrics. You can now achieve a custom fit without the long wait times traditionally associated with bespoke tailoring.

Imagine ordering a garment tailored precisely to your measurements and receiving it in a fraction of the time. This isn't a distant dream; it's happening now.

Rapid prototyping is a game changer in this space. It allows you to see a tangible sample of your design in mere days, if not hours. This acceleration in the production cycle means you can iterate quickly, fine-tuning every detail to perfection. Gone are the days of waiting weeks for a prototype that may or may not meet your expectations.

The seamless integration of technology and creativity is what sets on-demand manufacturing apart. You're in control, from the initial design to the final product, ensuring that every piece is unique to your vision.

Embrace this shift towards customization and see how it can elevate your textile experience to new heights. The future of the textile market is here, and it's tailored just for you.

Market Globalization

As market globalization accelerates, the textile industry is positioned to experience significant shifts in production and distribution. Market potential is expanding in emerging regions, opening new avenues for growth and investment. Countries like Vietnam, Bangladesh, and Ethiopia are becoming hotspots for textile manufacturing, offering competitive labor costs and increasing production capabilities.

Trade agreements play a pivotal role in shaping the global impact of these shifts. Agreements like the USMCA and RCEP are dismantling trade barriers, making it easier to source materials and distribute products across borders. This global integration isn't just a trend but a strategic necessity for staying competitive in today's market.

To master this evolving landscape, consider these three key strategies:

- Diversify Supply Chains: Don't rely on a single region. Spread manufacturing across multiple emerging regions to mitigate risks and tap into various market strengths.

- Leverage Trade Agreements: Stay informed about new and existing trade agreements to maximize benefits and reduce costs.

- Embrace Technology: Utilize advanced logistics and supply chain management software to streamline operations and guarantee timely deliveries.

Frequently Asked Questions

What Are the Upcoming Trends in Textile Design Aesthetics?

You're seeing a shift towards sustainable materials, innovative technologies, and eco-friendly practices in textile design. You'll notice designers embracing recycled fabrics, smart textiles, and 3D printing to create cutting-edge, environmentally-conscious fashion pieces.

How Will Climate Change Impact Textile Production?

You'll see climate change driving textile production towards sustainability initiatives. Technological advancements will enable eco-friendly materials and processes, ensuring reduced environmental impact. Mastering these changes is essential for future-proofing your textile operations.

What Role Will Government Policies Play in the Future Textile Market?

You'll see government regulations and sustainability initiatives playing vital roles. They'll drive the adoption of eco-friendly practices, ensuring the textile industry meets environmental standards while fostering innovation and competitiveness. Master these policies to stay ahead.

How Is the Workforce in Textile Manufacturing Expected to Evolve?

You'll see significant evolution in the textile workforce. Automation integration will streamline processes, but you must also seize skill development opportunities to stay competitive. Embrace continuous learning to master new technologies and enhance your industry expertise.

What Are the Future Challenges for Textile Supply Chains?

Imagine a tightrope walker balancing precariously: that's the textile supply chain maneuvering future challenges. You'll need to implement robust sustainability practices and adapt to shifting global trade relations to maintain equilibrium and thrive.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024