You might not know that some modern fabrics can be up to 15 times stronger than steel by weight. When you explore the tensile strength of advanced fibers like Kevlar and Dyneema, you'll discover how these materials handle extreme stress while remaining lightweight and flexible. Blending these synthetics with natural fibers can create textiles that not only offer exceptional durability but also maintain comfort and versatility. By examining the methods used in both laboratory stress analysis and real-world testing, you'll see how fiber composition plays an essential role in fabric innovation.

Table of Contents

Key Takeaways

- Tensile strength measures a fabric's maximum stress before breaking, essential for evaluating durability.

- Advanced fibers like Kevlar and Dyneema offer exceptional tensile strength and performance.

- Blending natural fibers with synthetics enhances fabric tensile strength and environmental sustainability.

- Laboratory and real-world testing methods ensure reliable evaluation of fabric tensile strength.

- Innovations in textile engineering, such as nanotechnology and smart textiles, are enhancing fabric properties and applications.

Understanding Tensile Strength

Understanding the concept of tensile strength is crucial when evaluating the durability of modern fabrics. In textile engineering, tensile strength refers to the maximum amount of tensile stress a material can withstand before failing or breaking. You need to grasp this concept to assess fiber durability accurately.

It's not just about how strong a fabric is but how it performs under continuous stress and strain. Think of tensile strength as the backbone of fabric integrity. When you're considering different textiles, you'll often compare how much force they can handle before they start to tear.

This knowledge is crucial for creating materials that are both strong and versatile. Textile engineers meticulously test fabrics to measure their tensile strength, ensuring they can withstand various applications, from everyday wear to extreme conditions.

Key Materials in Modern Fabrics

When exploring modern fabrics, you'll find that advanced synthetic fibers and natural fiber blends play important roles. These materials have a notable impact on tensile strength, offering unique benefits for various applications.

Let's examine how each contributes to the durability and performance of today's textiles.

Advanced Synthetic Fibers

Among the most significant advancements in modern textiles, advanced synthetic fibers like Kevlar and Dyneema are revolutionizing fabric durability and tensile strength. These high-performance materials are engineered to withstand extreme conditions, providing exceptional fiber durability and performance.

When you opt for fabrics incorporating these fibers, you're choosing materials that excel in both resilience and longevity.

Kevlar, known for its use in bulletproof vests, offers unmatched tensile strength and resistance to abrasion. On the other hand, Dyneema, often referred to as the world's strongest fiber, combines extraordinary strength with light weight. Both fibers are game-changers in applications requiring robust materials without compromising fabric flexibility and durability.

You'll find these advanced fibers in a variety of products, from outdoor gear to industrial applications. Their ability to endure harsh environments while maintaining flexibility makes them ideal for demanding uses.

When you incorporate these fibers into your projects, you're not just enhancing durability; you're elevating the overall performance of the fabric.

Natural Fiber Blends

In the world of modern textiles, combining natural fibers like cotton, wool, and silk with synthetic materials creates fabrics that offer the best of both worlds. These natural fiber blends not only enhance the tensile strength of fabrics but also cater to the growing demand for sustainable options.

By meticulously examining durability studies, you can appreciate the advanced properties these blends bring to modern fabrics.

When you explore natural fiber blends, you'll notice several key benefits:

- Enhanced Strength: Blending natural fibers with synthetics can significantly improve tensile strength, making fabrics more resistant to wear and tear.

- Sustainability: Using natural fibers like organic cotton or recycled wool aligns with sustainable options, reducing the environmental footprint of textile manufacturing.

- Comfort and Softness: Natural fibers are inherently comfortable and breathable. Blending them with synthetics can retain these qualities while improving durability.

- Versatility: Such blends are versatile and can be used in a wide range of applications, from fashion to home textiles, without compromising on performance.

Testing Methods

You'll want to understand how tensile strength is tested through laboratory stress analysis and real-world performance testing. These methods guarantee the fabric meets both scientific standards and practical demands.

Let's explore how each approach provides important insights into fabric durability.

Laboratory Stress Analysis

To accurately measure the tensile strength of modern fabrics, you'll find that several laboratory stress analysis methods come into play. These methods ensure the fabric's durability and give you a deeper understanding of its textile properties. By focusing on material stress and fabric testing, you can achieve a reliable evaluation of the fabric's performance capabilities.

Here are four key methods you'll employ in laboratory stress analysis:

- Tensile Testing Machine: This device stretches the fabric until it breaks, allowing you to determine its tensile strength. It provides detailed data on how the fabric behaves under stress, revealing its maximum load capacity and elongation.

- Strip Method: You'll cut the fabric into strips and subject them to tensile testing. This technique is straightforward and commonly used to compare different textile properties across various fabrics.

- Grab Test: In this method, only part of the fabric width is gripped, simulating real-world conditions where the whole width isn't uniformly stressed. It's particularly effective for evaluating material stress in woven fabrics.

- Ball Burst Test: Here, a ball is pushed through the fabric until it ruptures. This test is excellent for understanding the fabric's puncture resistance, adding another layer to your fabric testing arsenal.

Real-World Performance Testing

When evaluating fabrics for real-world applications, testing their performance under conditions that closely mimic everyday use is crucial. It's vital to go beyond laboratory settings and consider field applications to truly comprehend how a fabric will hold up.

Real-world performance testing involves subjecting fabrics to wear and tear that they'd encounter in actual use scenarios, such as abrasion, stretching, and exposure to elements like UV light and moisture.

To ensure your fabrics meet durability standards, you should utilize a variety of testing methods. Begin with abrasion tests, where the fabric is rubbed against a rough surface to simulate extended use. Follow up with tensile tests that measure how much force the fabric can withstand before breaking.

Remember to expose the fabric to environmental stressors. For instance, UV testing will help you determine how sunlight affects the material's strength and color over time.

Role of Fiber Composition

In evaluating tensile strength, fiber composition greatly impacts a fabric's durability and performance. When you look at the fibers, their inherent properties dictate how well the fabric will hold up under stress. Fiber durability is essential; fibers like Kevlar and Dyneema are renowned for their exceptional strength and resistance to wear.

On the other hand, fabric flexibility ensures that the textile can stretch and return to its original shape without breaking. This balance between strength and flexibility is crucial for applications ranging from athletic wear to industrial materials.

To help you understand the role of fiber composition, consider these key points:

- Natural Fibers: Cotton and wool offer excellent comfort and breathability but may lack the tensile strength required for high-stress applications.

- Synthetic Fibers: Nylon and polyester provide superior tensile strength and fiber durability, making them ideal for heavy-duty uses.

- Blended Fabrics: Combining natural and synthetic fibers can optimize both fabric flexibility and strength, giving you a versatile material.

- High-Performance Fibers: Specialized fibers like carbon and aramid are engineered for maximum strength and minimal weight, perfect for advanced technical applications.

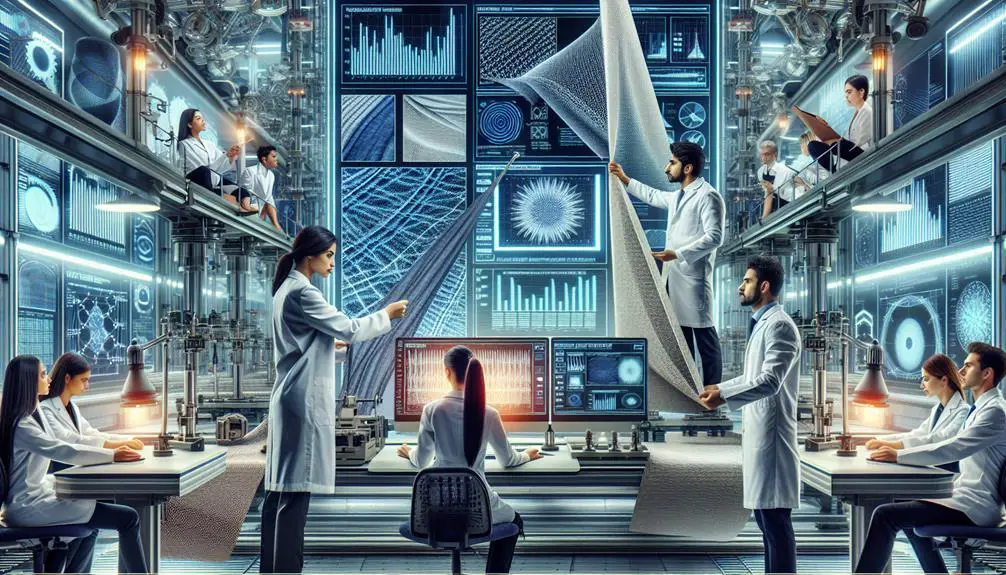

Innovations in Textile Engineering

Recent advancements in textile engineering are revolutionizing how fabrics are designed and utilized. You're witnessing an era where fabric durability and elasticity innovations are at the forefront. Engineers are leveraging cutting-edge materials and technologies to enhance the tensile strength of fabrics, ensuring they withstand greater stress and wear over time.

Imagine fabrics that can stretch and return to their original shape without losing integrity. Thanks to elasticity innovations, that's now a reality. These advancements aren't just about making fabrics stretchier; they're about maintaining durability even when subjected to repeated stretching and bending. It's a meticulous balance of strength and flexibility, achieved through molecular-level modifications and advanced weaving techniques.

You're also seeing the rise of smart textiles—fabrics embedded with electronic components that can monitor and adapt to environmental changes. These innovations are paving the way for textiles that respond dynamically to your needs, whether for better comfort, performance, or protection.

Applications in Sportswear

Building on these technological advancements, sportswear now benefits immensely from enhanced strength and elasticity. You'll find that these improvements translate directly into better longevity and flexibility, allowing athletes to push their limits without worrying about their gear. This combined strength and stretch also contribute to superior comfort and performance, making your sportswear an essential part of your athletic success.

Here are four key benefits you can expect from modern sportswear:

- Enhanced Longevity: The improved tensile strength ensures that your sportswear can withstand intense physical activity without tearing or wearing out quickly, thereby extending the lifespan of your gear.

- Increased Flexibility: Innovations in fabric elasticity mean you'll experience unrestricted movement, vital for high-performance activities. Whether you're sprinting, stretching, or lifting, your sportswear moves seamlessly with you.

- Superior Comfort: Lightweight and breathable materials, reinforced by advanced tensile properties, keep you comfortable during long workouts or competitions. Say goodbye to chafing and discomfort.

- Optimized Performance: With the perfect blend of strength and flexibility, your sportswear supports enhanced athletic performance. You can focus on your training without being hindered by your gear.

Industrial Uses

As industries demand more durable and flexible materials, modern fabrics with enhanced tensile strength are revolutionizing sectors from construction to aerospace. You'll find these advanced materials playing pivotal roles in fabric reinforcement and durability enhancement, transforming the way we build and protect.

In construction, these fabrics are integrated into concrete and other building materials to provide additional strength and longevity. This fabric reinforcement not only boosts the structural integrity but also reduces material fatigue over time.

In aerospace, the stakes are even higher. Safety considerations are paramount, and modern fabrics with high tensile strength contribute significantly to the manufacturing of aircraft and spacecraft. These fabrics are used in everything from the outer skin of aircraft to the interior components, ensuring they can withstand extreme conditions and stress. The result is lighter, stronger, and more durable vehicles that push the boundaries of what's possible.

Additionally, in the automotive industry, these fabrics enhance the durability of tires and other critical components, ensuring they perform under extreme stress and temperature variations. By integrating these advanced materials, you're not just improving safety and performance; you're setting new standards for future innovations.

Future Trends in Fabric Technology

Looking ahead, the future of fabric technology promises groundbreaking advancements that will redefine durability, flexibility, and functionality across various industries. As you explore these trends, you'll find that sustainable innovations and smart textiles are at the forefront of this revolution.

- Sustainable Innovations: Expect fabrics designed with eco-friendly materials and processes. Advances in recycling techniques and biodegradable fibers will minimize environmental impact. You'll see fabrics made from organic or recycled sources, reducing reliance on traditional, resource-intensive materials.

- Smart Textiles: Imagine clothing that adapts to your needs. Smart textiles integrate sensors and electronic components, allowing fabrics to monitor body temperature, heart rate, and even muscle activity. This technology is set to enhance both personal health and athletic performance.

- Self-Repairing Fabrics: Future fabrics might repair themselves when damaged. With self-healing polymers and microcapsule technology, minor tears and punctures could become a thing of the past. This innovation will significantly extend the lifespan of your garments.

- Adaptive Fabrics: These textiles will change properties in response to environmental conditions. Think of fabrics that adjust their breathability based on humidity or temperature, providing ideal comfort in any situation.

Frequently Asked Questions

How Does Tensile Strength Affect Fabric Durability in Everyday Use?

Did you know fabrics with higher tensile strength can last up to 50% longer? Increased tensile strength improves fabric longevity, reducing wear and tear, ensuring your garments withstand the rigors of everyday use remarkably well.

What Are the Environmental Impacts of High-Tensile Strength Fabric Production?

You'll find high-tensile strength fabric production impacts the environment through a significant carbon footprint and challenges in sustainability. Effective waste management and pollution control are essential to mitigating these adverse effects.

Can Traditional Fabrics Be Enhanced to Improve Tensile Strength?

Oh, you think traditional fabrics can't be enhanced? With fabric innovation and a sprinkle of traditional techniques, you can absolutely boost tensile strength. It's like giving grandma's quilt a superhero makeover.

How Does Tensile Strength Influence Fabric Cost and Affordability?

Tensile strength directly impacts fabric pricing. Higher strength increases production costs, which can affect market demand and affordability. You'll find that stronger fabrics often cost more, making affordability a key consideration for consumers and manufacturers alike.

Are There Any Health Risks Associated With High-Tensile Strength Fabrics?

You're right to ask about health risks. High-tensile strength fabrics can sometimes compromise comfort vs. strength. However, appropriate fabric safety standards guarantee you won't face significant health issues, making these materials generally safe to use.

- Sourcing Authentic Banarasi Katan Fabric: A Buyer’s Checklist - June 29, 2025

- A Glossary of Katan Fabric Terms You Should Know - June 29, 2025

- Can You Wear Katan Silk in Hot Weather? A Fabric Breakdown - June 29, 2025