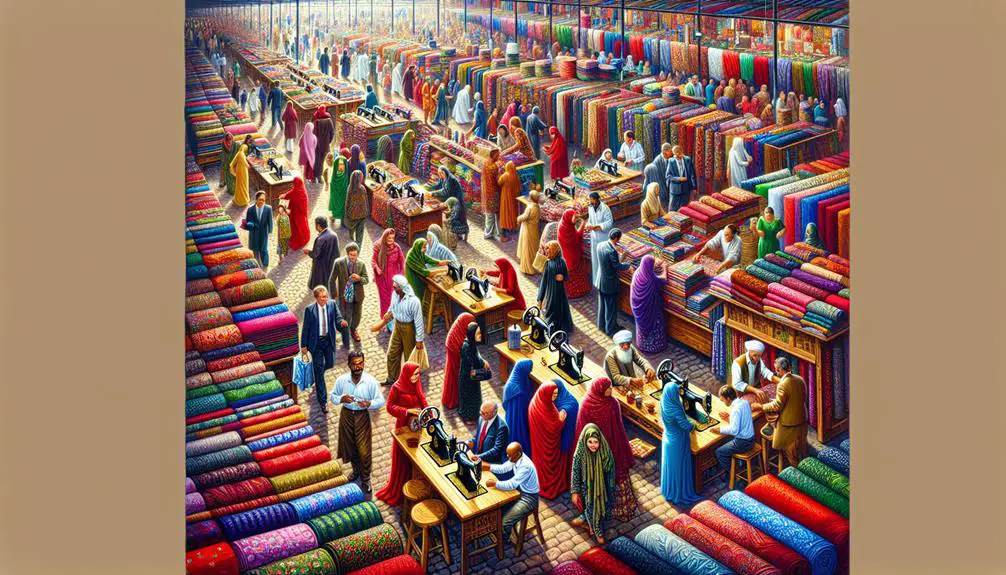

You're probably aware that the textile industry is undergoing significant changes, especially with the rise of sustainability and transparency. Brands now invest in biodegradable fibers and recycled fabrics to meet eco-friendly demands. But have you considered how these shifts affect pricing strategies and raw material costs? The emphasis on ethical sourcing and fair labor conditions also plays a pivotal role. As the industry leans towards a circular economy, innovative technologies are becoming essential. Curious about how these factors intertwine to shape the future of fabric economics? Let's explore the intricate dynamics and emerging opportunities together.

Table of Contents

Key Takeaways

- Sustainable fabrics and circular fashion models are gaining traction in response to consumer demand for eco-friendly practices.

- Technological advancements like AI and automation are revolutionizing textile manufacturing and supply chain efficiency.

- Market fluctuations and trade policies significantly impact raw material costs and availability in the textile industry.

- Fast fashion's rapid cycles necessitate agile inventory management and quick adaptation to consumer trends.

- Transparency in sourcing and labor practices is increasingly crucial for building trust and meeting consumer expectations.

Sustainable Fabric Innovations

In recent years, sustainable fabric innovations have revolutionized the textile industry by reducing environmental impact and promoting eco-friendly practices.

You've likely noticed the rise of circular fashion, a concept where products are designed, manufactured, and recycled with minimal waste. By incorporating materials that can be reused or repurposed at the end of their lifecycle, circular fashion guarantees that less waste ends up in landfills. This approach not only conserves resources but also aligns with a growing consumer demand for sustainability.

Biodegradable textiles play a pivotal role in this movement. Unlike traditional fabrics that can take centuries to decompose, biodegradable textiles break down naturally without releasing harmful chemicals into the environment. These materials, often derived from natural sources like organic cotton, hemp, or bamboo, decompose efficiently, leaving behind no toxic residue. By choosing biodegradable textiles, you're contributing to a cleaner, greener planet.

Mastering the principles of sustainable fabric innovations empowers you to make informed choices. By supporting circular fashion and opting for biodegradable textiles, you're not only enhancing your wardrobe but also promoting a more sustainable and responsible textile industry.

Impact of Technology

As sustainable fabric innovations continue to evolve, technology's impact on the textile industry has become increasingly significant. You're witnessing a digital transformation that reshapes how textiles are manufactured, distributed, and consumed. Automation efficiency is at the forefront, streamlining production processes and reducing labor costs. Advanced machinery and robotics aren't just enhancing productivity but also ensuring higher precision and quality. This shift reduces waste and boosts overall sustainability, aligning perfectly with contemporary environmental goals.

Market disruptions are inevitable as technology integrates further into the industry. Traditional business models are challenged by new, agile competitors who leverage digital tools to outpace their rivals. For instance, AI-driven design software enables rapid prototyping, cutting down the time from concept to market. Companies that fail to adapt to these changes risk obsolescence.

The industry evolution doesn't stop at production. Digital platforms are revolutionizing supply chain management, offering real-time tracking and predictive analytics. This transparency fosters better decision-making and more agile responses to market demands. By embracing these technological advancements, you can position yourself at the cutting edge of the fabric economy, ensuring you're not just keeping up but leading the way.

Raw Material Costs

Raw material costs play a pivotal role in determining the overall economics of fabric production. When you're looking to optimize production efficiency, understanding these costs is crucial. Market fluctuations can lead to unpredictable pricing, impacting your bottom line.

To navigate these challenges, you need to stay informed about several key factors:

- Market Fluctuations: Prices for raw materials like cotton, wool, and synthetic fibers can vary dramatically. Keep an eye on global market trends to anticipate changes and adjust your procurement strategies accordingly.

- Trade Policies: Government regulations and international trade agreements can influence the cost and availability of raw materials. Stay updated on tariffs, import duties, and export restrictions to mitigate potential impacts.

- Material Scarcity: Certain materials may become scarce due to environmental factors or supply chain disruptions. Diversify your sources to guarantee a steady supply and minimize risks associated with scarcity.

- Production Efficiency: Efficient use of raw materials can significantly lower costs. Implementing advanced manufacturing techniques and waste reduction practices will improve your overall production efficiency.

Supply Chain Dynamics

You need to address the complex issues of global sourcing challenges and effective inventory management strategies to guarantee a smooth fabric supply chain. By understanding these dynamics, you'll be better equipped to mitigate risks and optimize costs.

Let's explore how these factors impact your business operations.

Global Sourcing Challenges

Managing global sourcing challenges demands a keen understanding of supply chain dynamics and their impact on fabric availability. You must navigate complex factors like trade tariffs and production delays that can disrupt your supply chain.

To ensure a steady flow of high-quality fabrics, consider the following strategies:

- Stay Informed: Keep up-to-date with changes in international trade policies and tariffs. These can significantly affect your cost structure and delivery timelines.

- Diversify Suppliers: Relying on a single source can be risky. Diversify your supplier base to mitigate risks related to production delays and geopolitical tensions.

- Quality Control: Implement rigorous quality control checks to ensure the fabrics meet your standards. Poor quality can lead to unsellable inventory and financial losses.

- Ethical Sourcing: Prioritize suppliers who follow ethical labor practices. This not only ensures compliance with regulations but also enhances your brand's reputation.

Mastering these aspects will help you manage the complexities of global sourcing. By adopting these strategies, you can better navigate the labyrinth of supply chain dynamics, securing a reliable and ethical supply of quality fabrics.

Inventory Management Strategies

Effectively managing global sourcing challenges sets the stage for robust inventory management strategies within your supply chain. To master these strategies, you need to focus on enhancing just-in-time practices and improving forecasting accuracy.

Just-in-time (JIT) inventory management minimizes waste by receiving goods only as they're needed in the production process. This approach requires precise prediction accuracy to ensure that materials arrive exactly when required, reducing storage costs and avoiding overstock.

Demand planning plays a pivotal role in maintaining an efficient supply chain. Accurate demand planning helps you predict customer needs, thereby optimizing inventory levels and minimizing shortages or excesses. Coupled with lead times, which are the periods between ordering and receiving materials, effective demand planning guarantees that your supply chain remains agile and responsive.

Lead times can greatly impact your inventory management. By understanding and reducing lead times, you can better align your inventory levels with actual demand, enhancing your overall supply chain efficiency. Implementing these strategies will enable you to maintain a lean inventory, lower costs, and improve customer satisfaction.

Mastering these elements is essential for staying competitive in the dynamic fabric economics landscape.

Consumer Demand Shift

You've probably noticed consumers increasingly favor eco-friendly materials, pushing brands to adopt sustainable practices.

At the same time, fashion cycles are getting shorter, demanding quicker responses from manufacturers.

This shift in consumer preferences is reshaping the entire fabric industry.

Eco-friendly Materials Rise

Consumers are increasingly demanding eco-friendly materials, driving a significant shift in the fabric industry. As an eco-conscious consumer, you're likely familiar with the push towards sustainable practices. This shift prioritizes the circular economy and embraces biodegradable fibers. Companies are responding by integrating green manufacturing techniques, ensuring that the entire lifecycle of the product minimizes environmental impact.

Consider these benefits of eco-friendly materials:

- Reduced Waste: Biodegradable fibers break down naturally, contributing less to landfill overflow.

- Energy Efficiency: Green manufacturing techniques often consume less energy, cutting down on carbon footprints.

- Sustainable Growth: A circular economy supports recycled and upcycled materials, reducing the need for virgin resources.

- Healthier Choices: Natural fibers often avoid harmful chemicals, making them safer for both the environment and consumers.

Fashion Cycles Shorten

Fashion cycles are shortening rapidly, driven by a shift in consumer demand for the latest trends. You notice that fast fashion brands capitalize on this shift by continuously updating their collections to align with the ever-evolving tastes of consumers. This change in consumer behavior reflects a desire for immediacy and novelty, pushing the fashion industry to accelerate its production schedules.

To better understand this dynamic, consider the following table:

| Aspect | Traditional Fashion | Fast Fashion |

|---|---|---|

| Cycle Duration | Seasonal (4-6 months) | Weekly/Monthly |

| Consumer Purchase Frequency | Occasional | Frequent |

| Trend Adoption Speed | Slow | Rapid |

You can see that traditional fashion cycles span several months, whereas fast fashion operates on a much quicker timeline, with new trends emerging almost weekly. This rapid cycle affects not just how often consumers buy clothes, but also how quickly trends come and go.

Transparency in Textiles

In an industry where hidden practices often prevail, transparency in textiles is becoming an essential demand. You're now seeing a shift towards greater openness in how fabrics are sourced and produced. Companies that prioritize ethical sourcing and fair labor conditions are gaining favor. Consumers want to know if the people making their clothes are treated well and paid fairly.

To master this trend, you need to focus on:

- Ethical sourcing: Guarantee that the raw materials are obtained in a manner that respects both people and the environment.

- Labor conditions: Verify that the workers involved in textile production operate under safe, humane conditions and are compensated justly.

- Green certifications: Look for certifications that confirm the sustainability of a product, indicating responsible environmental practices.

- Chemical use: Be aware of the chemicals used in the production process, aiming for minimal and non-toxic options.

This enhanced transparency not only builds trust but also aligns with the growing consumer demand for responsible fashion. By embracing these principles, you're not just keeping up with the current trend; you're leading the way in setting higher standards for the entire industry.

Pricing Trends

Analyzing pricing trends in the textile industry reveals significant shifts driven by consumer demand for sustainable and ethically-produced fabrics. You've likely noticed that market competition has intensified, pushing companies to adopt innovative pricing strategies. Brands are now balancing the higher costs of eco-friendly materials with competitive pricing to attract discerning consumers like yourself.

An economic downturn can further complicate fabric pricing trends. When the economy slows, consumers often become more price-sensitive, forcing companies to reconsider their pricing structures. However, rather than simply slashing prices, many are opting for value-based pricing strategies. This means emphasizing the long-term benefits and durability of their sustainable fabrics to justify the cost.

You're also seeing a rise in dynamic pricing, where brands adjust prices in real-time based on demand and inventory levels. This flexibility can help companies stay competitive without compromising their commitment to sustainability.

Besides, transparent pricing is gaining traction. By clearly communicating the cost breakdown of eco-friendly fabrics, brands can build trust and justify higher prices.

Availability Challenges

You're likely aware that sourcing sustainable fabrics often presents significant availability challenges for many brands. These issues can stem from various factors within the supply chain, making it difficult to maintain a steady flow of materials. For brands aiming for sustainability, understanding these challenges is essential.

First, production delays are a common problem. Whether it's due to environmental conditions or labor shortages, delays can severely impact your timeline.

Second, limited supplier options for sustainable materials can create bottlenecks. Unlike conventional fabrics, sustainable alternatives often have fewer producers, making it harder to find reliable sources.

Third, logistical hurdles can exacerbate availability issues. Transportation disruptions or geopolitical tensions can further complicate your supply chain.

Fourth, regulatory compliance adds another layer of complexity. Ensuring that your materials meet all environmental standards can slow down the procurement process.

Here's a quick recap:

- Production Delays: Environmental conditions and labor shortages can disrupt timelines.

- Limited Supplier Options: Fewer producers of sustainable materials lead to bottlenecks.

- Logistical Hurdles: Transportation disruptions and geopolitical tensions impact supply chains.

- Regulatory Compliance: Meeting environmental standards can slow procurement.

Future of Fabric Economics

As we move past the availability challenges, let's explore how advancements and innovations are shaping the future of fabric economics.

You'll find that textile recycling is becoming a cornerstone of the industry. By integrating a circular economy model, the textile sector aims to reduce waste and extend the lifecycle of fabrics. This shift not only conserves resources but also drives economic value through sustainable practices.

Consumer behavior is also undergoing a significant transformation. Today's consumers are more conscious of their fabric consumption habits. They're demanding transparency and sustainability from brands, influencing how companies source and produce textiles. As a result, businesses are investing in eco-friendly materials and innovative recycling technologies.

Moreover, advancements in smart textiles promise to revolutionize fabric economics. These fabrics, embedded with sensors and electronic components, offer new functionalities that go beyond traditional uses. This innovation opens up new market opportunities and diversifies revenue streams.

Frequently Asked Questions

How Do Geopolitical Events Affect Global Fabric Markets?

Geopolitical events impact global fabric markets by causing currency fluctuations and supply chain disruptions. Tariffs and sanctions can further complicate trade, making fabric more expensive and less accessible, challenging your ability to maintain competitive pricing.

What Are the Labor Cost Trends in Textile-Producing Countries?

You're seeing labor cost trends in textile-producing countries shift due to automation's impact and rising labor wages. Technology advancements are reducing production costs, yet balancing these savings with fair wages remains a critical challenge for the industry.

How Does Climate Change Impact Fabric Production?

Oh, you thought climate change wouldn't affect fabric production? Think again. Resource scarcity and sustainability challenges push the industry to adopt technology innovation and automation. Mastering these shifts is crucial for future-proofing your textile operations.

What Role Do Trade Policies Play in Fabric Economics?

You'll find that trade policies directly influence fabric economics by setting tariffs and quotas, which affect pricing and availability. They shape international competition, impacting both domestic producers and global market dynamics.

How Are Emerging Markets Influencing Global Fabric Economics?

When you explore how emerging markets impact global fabric economics, you'll see they shake up the supply chain and alter consumer behavior. Their growth drives demand, creating a ripple effect felt by manufacturers and consumers alike.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024