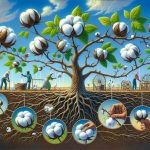

Ever wondered how your favorite shirt came to be? From the very beginning, cotton fabric goes on a captivating journey. You’ll be amazed as you follow the process from seed to shirt.

First, you’ll witness the planting of the cotton seeds and the careful harvesting of the crop.

Then, you’ll see the raw cotton being processed, spun into yarn, and woven into fabric.

Finally, you’ll learn about the manufacturing process that transforms fabric into the shirt you love.

Get ready for an eye-opening adventure!

Table of Contents

Planting the Cotton Seeds

To begin planting the cotton seeds, you’ll need to prepare the soil and choose the optimal time for sowing. The first step is to select the right cotton seed varieties that are suitable for your region and climate. Different varieties have varying resistance to pests and diseases, as well as different fiber qualities. By choosing the right varieties, you can ensure a higher chance of success in optimizing cotton yields.

Once you have selected the appropriate seed varieties, it’s time to prepare the soil. Cotton thrives in well-drained soil with a pH level between 5.8 and 7.5. You’ll need to remove any weeds or debris from the field and incorporate organic matter to improve soil fertility. This will provide a favorable environment for the cotton seeds to germinate and establish strong root systems.

Timing is crucial when it comes to sowing cotton seeds. The optimal time for planting varies depending on your location. Generally, cotton seeds are sown when the soil temperature reaches around 60°F (15.5°C) and there’s no longer a risk of frost. This ensures that the seeds will germinate and grow vigorously.

Harvesting the Cotton Crop

When harvesting the cotton crop, you’ll need to carefully remove the mature cotton bolls from the plants. This is a crucial step in the process of transforming cotton into fabric. To effectively harvest the cotton, there are several methods and equipment you can use:

-

Handpicking: This traditional method involves manually picking the cotton bolls from the plants. It requires skilled laborers who can carefully select only the mature bolls, leaving the unripe ones on the plant for future harvesting.

-

Mechanical pickers: These machines are designed to mechanically harvest the cotton crop. They use rotating spindles to grab the cotton bolls and remove them from the plants. Mechanical pickers are efficient and can cover a large area in a shorter period.

-

Stripper harvesters: These machines remove not only the cotton bolls but also the entire plant. They use rotating bars or brushes to strip the cotton from the plants. The harvested cotton is then separated from the leaves and stems using specialized equipment.

-

Cotton harvesters: These advanced machines combine the functionalities of mechanical pickers and stripper harvesters. They can selectively harvest the cotton bolls without damaging the plants, resulting in higher-quality cotton.

With the use of these cotton picking methods and harvesting equipment, farmers can efficiently collect the mature cotton bolls, ensuring a successful cotton crop harvest.

Processing the Raw Cotton

Now let’s talk about how the raw cotton is processed.

First, the cotton goes through the ginning process, where the seeds are removed and the fibers are separated.

Then, the fibers are spun into thread, ready to be woven into fabric.

This processing stage is essential in transforming the raw cotton into the fabric that will eventually become your shirt.

Ginning Process Explained

First, you’ll need to remove the seeds from the raw cotton using a machine called a gin. The ginning process is an essential step in cotton processing, with both benefits and challenges.

Benefits of the ginning process:

- Separates the cotton fibers from the seeds.

- Improves the quality of the cotton fibers for spinning and weaving.

- Increases the yield of usable cotton.

- Reduces the risk of contamination from impurities.

Challenges of the ginning process:

- Requires careful handling to prevent fiber damage.

- Inefficient ginning methods can result in fiber loss.

- Maintaining the gin machinery can be costly.

- Environmental concerns, such as waste disposal.

Spinning Into Thread

To begin processing the raw cotton, you’ll need to spin it into thread. Thread spinning techniques have evolved over time, but the historical significance of spinning remains unchanged.

Spinning is the process of twisting fibers together to create a continuous strand of thread. In the past, this was done by hand using a spinning wheel or drop spindle. However, with advancements in technology, spinning can now be done using machines. These machines can spin cotton fibers into thread at a much faster rate, increasing productivity and efficiency.

Despite the modernization of spinning techniques, the art of hand spinning is still practiced today, preserving the traditional methods and skills of the past.

Weaving the Fabric

After spinning the cotton fibers into thread, you can now move on to weaving the fabric by processing the raw cotton. This crucial step in the textile industry involves using loom technology to create the fabric we know and love.

Here are four key aspects of weaving that you might find interesting:

-

Looms: Looms are machines used to weave fabric. They come in various types, including handlooms and power looms.

-

Warp and Weft: The warp refers to the vertical threads, while the weft refers to the horizontal threads. Weaving involves interlacing these threads to create the fabric.

-

Shedding: Shedding is the process of raising and lowering the warp threads to create an opening for the weft thread to pass through.

-

Beat-up: After each weft thread is inserted, it’s pushed tightly against the previously woven fabric using a comb-like tool called a beater or reed.

Through these steps, the raw cotton is transformed into a beautiful woven fabric ready for the next stage of garment production.

Spinning the Cotton Into Yarn

Once the cotton fibers have been harvested, the next step in the process is to spin them into yarn. Yarn production is a crucial part of the textile industry, as it’s the foundation for creating fabrics and ultimately, clothing.

To turn cotton fibers into yarn, they undergo a series of steps. First, the cotton fibers are cleaned and carded, which involves removing any impurities and aligning the fibers in the same direction. This makes the spinning process easier and ensures a more consistent yarn.

After carding, the fibers are then drawn, which stretches and straightens them further. This helps to create a finer and more even yarn. The drawn fibers are then twisted together through a process called spinning. Spinning can be done by hand or using mechanical spinning machines, which increase efficiency and productivity.

During spinning, the fibers are twisted together to form a continuous strand of yarn. The twist provides strength and stability to the yarn, making it suitable for weaving or knitting. Once the yarn is spun, it can be further processed, such as being dyed or treated for different properties like softness or flame resistance.

Spinning cotton fibers into yarn is a critical step in the textile industry. It transforms the raw material into a versatile and usable form, allowing for the creation of various fabrics and garments.

Weaving the Yarn Into Fabric

Now it’s time to weave the yarn into fabric.

You’ll explore different types of yarn and their properties, comparing traditional weaving techniques with modern ones.

Additionally, you’ll discover various fabric finishing techniques that enhance the texture, appearance, and durability of the final product.

Get ready to unravel the fascinating process of turning yarn into beautiful cotton fabric.

Yarn Types and Properties

To weave the yarn into fabric, you’ll need to understand the different types and properties of yarn. Here are some key points to consider:

-

Yarn Manufacturing: Yarn is made by spinning fibers together. The process can vary, including methods like ring spinning, open-end spinning, and air-jet spinning. Each method produces yarn with different characteristics.

-

Yarn Properties: Yarn has various properties that affect the final fabric. These include yarn count (thickness), twist (tightness of the fibers), and strength. The type of fiber used, such as cotton, polyester, or wool, also influences the properties.

-

Yarn Twist: The twist of the yarn plays a crucial role in determining the fabric’s strength and appearance. Low twist yarns create a soft and drapey fabric, while high twist yarns result in a more structured and durable fabric.

-

Yarn Count: Yarn count refers to the thickness or fineness of the yarn. It’s measured in terms of the number of units per length, such as ‘count per inch’ or ‘ne’. Finer yarns produce lightweight fabrics, while thicker yarns create heavier and more textured fabrics.

Understanding these yarn types and properties is essential for weaving high-quality and desired fabrics.

Traditional Vs. Modern Weaving

As you weave the yarn into fabric, you can explore the differences between traditional and modern weaving techniques.

Traditional weaving techniques have been passed down through generations and involve manual labor, where skilled weavers use handlooms to create intricate patterns and designs. These methods require time and effort, but they’re valued for their craftsmanship and cultural significance.

On the other hand, modern textile innovations have revolutionized the weaving process. With the advent of power looms and computerized technology, fabrics can now be produced at a faster rate and with greater precision. These advancements have led to increased efficiency and productivity in the textile industry.

However, some argue that traditional weaving techniques hold a certain charm and authenticity that can’t be replicated by modern methods. The choice between traditional and modern weaving ultimately depends on the desired outcome and the values of the weaver.

Fabric Finishing Techniques

You can explore the process of fabric finishing techniques, which involve weaving the yarn into fabric, building upon the discussion of traditional and modern weaving techniques. Once the yarn is woven, various fabric finishing techniques are employed to enhance the fabric’s appearance and functionality.

Here are some popular methods:

-

Fabric dyeing techniques: This involves immersing the fabric in a dye bath to infuse it with color. Techniques such as tie-dye, dip-dye, and ombre are used to create unique patterns and gradients.

-

Fabric printing methods: Printing allows for intricate designs to be applied onto the fabric’s surface. Techniques like block printing, screen printing, and digital printing enable the creation of stunning patterns and motifs.

-

Embossing: This technique creates raised or textured patterns on the fabric, adding a tactile element.

-

Finishing treatments: Various treatments such as calendering, brushing, and sanding are applied to give the fabric its desired texture, smoothness, or softness.

From Fabric to Shirt: Manufacturing Process

Start by choosing the cotton fabric you want to transform into a shirt. Once you have selected the fabric, it’s time to dive into the manufacturing process. The journey from fabric to shirt presents various manufacturing challenges that need to be overcome. One of the key challenges is ensuring sustainability practices throughout the entire process.

To begin, the fabric is cut into specific patterns that will later be sewn together to form the shirt. Precision is crucial here to ensure that each piece fits perfectly. Next, the cut pieces are sewn together using sewing machines or, in some cases, by skilled artisans. This stage requires attention to detail and expertise to create a high-quality garment.

After the shirt is sewn, it undergoes various finishing processes. This can include adding buttons, buttonholes, cuffs, collars, and other details that give the shirt its final appearance. Quality control is essential at every step to maintain the desired standard.

Finally, the shirts are pressed, packaged, and prepared for distribution. Sustainability practices are incorporated throughout the manufacturing process, such as using eco-friendly dyes, reducing water consumption, and ensuring ethical labor practices.

Frequently Asked Questions

How Long Does It Take for Cotton Seeds to Germinate and Grow Into Mature Plants?

It takes about 7-14 days for cotton seeds to germinate and grow into mature plants. During this time, the seeds absorb water, sprout, and form roots. The plants then continue to grow and develop until they are ready for harvest.

What Are the Main Challenges Faced During the Harvesting Process of Cotton Crops?

During the harvesting process of cotton crops, you’ll face various challenges. These may include unpredictable weather conditions, labor-intensive tasks, and the need for specialized machinery to efficiently collect the cotton bolls.

How Is Raw Cotton Cleaned and Prepared Before It Is Sent for Processing?

Before processing, raw cotton must be cleaned and prepared. This ensures that any impurities, such as dirt and seeds, are removed. The cleaning process involves techniques like ginning and grading to ensure high-quality cotton for further processing.

What Are the Different Techniques Used to Spin Cotton Into Yarn?

To spin cotton into yarn, various techniques are used. These spinning techniques play a crucial role in yarn production. They help transform the raw cotton fibers into strong and durable threads for weaving or knitting.

Are There Any Specific Factors That Affect the Quality and Durability of Cotton Fabric During the Weaving Process?

Factors like the fineness of the cotton fibers, the tension applied during weaving, and the skill of the weaver all impact the quality and durability of cotton fabric during the weaving process.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024