Are you curious about the impact of quality on cotton production?

In this article, we will explore how various factors affect the quality of cotton, such as fiber length, strength, and micronaire.

By understanding these aspects, you can maximize the quality of your cotton crop, leading to increased profitability.

So, let’s dive in and compare the different ways quality can influence cotton production.

Table of Contents

Factors Affecting Cotton Quality

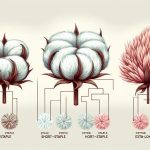

To understand the factors affecting cotton quality, you need to examine the impact of various variables on the final product. One of the primary factors that determine cotton quality is the adherence to grading standards. Grading standards provide a framework for evaluating the quality of cotton based on specific criteria such as fiber length, strength, and uniformity. These standards ensure consistency in the evaluation process and help to maintain a certain level of quality across the industry.

Another factor that affects cotton quality is the variations that can occur within a single batch of cotton. Even within a specific grade, there can be differences in fiber properties that can impact the final product. These variations can be influenced by factors such as weather conditions, cultivation practices, and harvesting techniques. It’s important for cotton producers to carefully monitor and manage these variables to minimize the impact on quality.

Importance of Fiber Length

Fiber length, which is an essential aspect of cotton quality, further enhances the overall value of the crop by influencing its strength and versatility. The measurement of fiber length plays a crucial role in determining the quality of cotton. Here are a few key points to understand the importance of fiber length:

-

Increased Strength: Longer fibers tend to be stronger, resulting in higher quality cotton. The longer the fibers, the better the yarn and fabric produced from it, making it highly desirable in the textile industry.

-

Enhanced Versatility: Longer fibers offer greater versatility in terms of their potential uses. They can be spun into finer yarns, resulting in softer and more comfortable fabrics. Additionally, longer fibers have better dye absorption, resulting in vibrant and long-lasting colors.

-

Improved Processability: Longer fibers are easier to process during spinning and weaving, reducing the chances of breakage or damage. This improves overall production efficiency and reduces waste, making it more cost-effective for manufacturers.

-

Increased Cotton Value: The impact of fiber length on cotton value can’t be overstated. Cotton with longer fibers commands a higher price in the market due to its superior quality and increased demand from textile manufacturers.

Understanding the importance of fiber length measurement and its impact on cotton value is crucial for cotton farmers, textile manufacturers, and consumers alike.

Significance of Fiber Strength

You can further understand the impact of quality on cotton production by recognizing the significance of fiber strength. Fiber strength refers to the ability of cotton fibers to withstand stress without breaking. It plays a crucial role in determining the overall quality of cotton and its market value. Cotton with higher fiber strength is more durable and less likely to break during processing, resulting in higher yields and better-quality end products.

To evaluate fiber strength, fiber strength testing is conducted using instruments such as High Volume Instrument (HVI) or Single Fiber Strength Tester (SFST). These tests measure the force required to break a single fiber and provide valuable information about the strength characteristics of the cotton.

Improving fiber strength is essential for enhancing cotton production. By breeding cotton varieties with higher fiber strength traits, farmers can ensure a more robust and resilient crop. Additionally, proper agronomic practices such as appropriate irrigation, fertilization, and pest control can contribute to improved fiber strength.

The table below illustrates the significant impact of fiber strength on cotton production:

| Fiber Strength | Impact on Cotton Production |

|---|---|

| High | Higher yields |

| Better-quality end products | |

| Low | Lower yields |

| Increased processing losses |

Understanding Micronaire in Cotton

One important aspect to understand in cotton production is the role of micronaire, a quantifier determiner that measures the fineness and maturity of cotton fibers. Micronaire measurement is crucial in determining the quality and market value of cotton.

Here are some key points to help you understand micronaire in cotton:

-

Micronaire is a measure of the average thickness of cotton fibers. It’s determined by the airflow resistance of a sample of cotton placed in a micronaire instrument.

-

Micronaire values range from low to high, indicating the maturity and fineness of the fibers. Low micronaire values indicate immature fibers, while high values suggest mature fibers.

-

Cotton with an optimal micronaire value is desirable as it ensures better spinning efficiency and yarn quality. It also affects the dye absorption, fabric appearance, and overall performance of the finished textile product.

-

Micronaire values can vary depending on cotton variety, growing conditions, and harvesting techniques. It’s essential to monitor and control micronaire throughout the cotton production process to maintain consistent fiber quality.

Understanding micronaire in cotton is crucial for cotton producers, textile manufacturers, and buyers. By monitoring micronaire measurement and ensuring the maturity of cotton fibers, stakeholders can optimize their production processes and enhance the quality of cotton products.

Maximizing Cotton Quality for Profitability

To maximize cotton quality for profitability, it’s important to understand the factors that contribute to fiber excellence. One key factor is improving cotton yield. By adopting modern farming techniques such as precision agriculture and using genetically modified seeds, farmers can increase the quantity of cotton produced per acre. This not only boosts profitability but also ensures a larger pool of high-quality fibers to work with.

Enhancing cotton processing is another crucial aspect. By investing in state-of-the-art processing equipment and technology, cotton can be processed more efficiently, resulting in higher quality fibers. This includes steps such as ginning, carding, and spinning, which must be carefully executed to maintain fiber integrity.

Furthermore, it’s essential to prioritize proper storage and handling of cotton to prevent contamination or damage. Implementing best practices in storage and transportation, such as using clean and dry containers, can significantly contribute to maintaining cotton quality.

Additionally, regular monitoring and testing of cotton at various stages of production can help identify any potential issues that may impact fiber quality. This allows for timely corrective measures to be taken, ensuring consistent excellence.

Frequently Asked Questions

How Does the Weather Affect Cotton Quality?

Weather patterns and soil conditions greatly impact the quality of cotton. The weather affects how the cotton plants grow, while soil conditions determine the nutrients available to the plants. Both factors play a crucial role in determining cotton quality.

What Are the Main Factors That Determine the Color of Cotton Fibers?

Factors influencing the color of cotton fibers include genetics, growing conditions, and processing methods. To enhance the color, you can use dyeing techniques or select cotton varieties known for their vibrant hues.

How Does the Presence of Pests and Diseases Affect Cotton Quality?

Pests and diseases have a significant impact on cotton quality. The use of pesticides can affect the quality of cotton negatively, while climate change can also lead to decreased quality.

Can the Quality of Cotton Be Improved Through Genetic Modification?

Yes, you can improve the quality of cotton through genetic modification. Genetically modified cotton can increase yield and improve sustainability. However, ethical concerns surround the genetic modification of cotton.

What Role Does Harvesting and Ginning Play in Determining Cotton Quality?

Harvesting and ginning play a crucial role in determining cotton quality. Mechanical harvesting can impact the quality, while the gin machinery further influences it. Both processes should be carefully managed to ensure high-quality cotton production.

- Recycling Nonwoven Fabrics: Is It Possible? - July 11, 2025

- Recycling Nonwoven Fabrics: Is It Possible? - July 11, 2025

- Recycling Nonwoven Fabrics: Is It Possible? - July 11, 2025