Coincidentally, woven fabrics hold a fascinating array of characteristics that go beyond their surface appeal. From the intricacies of thread count to the importance of cloth balance and understanding selvage, each aspect plays a vital role in determining the fabric's overall quality and performance.

As we navigate through the texture, durability, and versatility of woven fabrics, one can't help but wonder about the hidden complexities that contribute to their timeless popularity across different sectors.

Key Takeaways

- Thread count and cloth balance are crucial for woven fabric stability and draping.

- Durability is ensured through tightly woven threads, providing strength and resilience.

- Proper tension and shape retention contribute to garment construction and longevity.

- High-quality woven fabric endures various applications and industries, offering reliable performance.

Thread Count of Woven Fabric

When evaluating the quality of woven fabric, the thread count serves as a key indicator of its density and overall excellence. Thread count refers to the number of threads, both warp, and weft, present in a square inch of fabric.

A higher thread count signifies a finer, smoother fabric, while a lower count indicates a coarser texture. This measurement impacts various aspects of the fabric, including its durability, softness, and overall feel.

Fabrics with higher thread counts are often considered more luxurious due to their smoother, more tightly woven nature. Understanding thread count is essential for discerning the quality and characteristics of woven fabrics, as it directly influences how the fabric looks and feels.

Importance of Cloth Balance

Maintaining proper cloth balance in woven fabrics is important for ensuring fabric stability, proper draping, and enhancing garment durability. Without the right balance between warp and filling yarns, issues like yarn slippage and fabric distortion can occur, affecting the overall quality of the textile.

Achieving ideal cloth balance is essential, especially for items like shirts and towels that undergo frequent washing and wear.

Maintaining Fabric Stability

Achieving fabric stability hinges on the critical balance between warp and filling yarns in woven fabric construction.

Four key points help maintain fabric stability:

- Proper Tension: Ensuring equal tension in both warp and filling yarns prevents distortion and maintains fabric integrity.

- Regular Inspections: Periodic checks for any signs of imbalance or tension variations can help catch issues early on.

- Correct Storage: Storing fabric rolls in a way that preserves their alignment and prevents shifting is pivotal for stability.

- Careful Handling: Gentle handling during production and transportation minimizes the risk of disrupting the fabric's balance.

Understanding and actively managing these factors are essential for ensuring the longevity and quality of woven fabrics.

Ensuring Proper Draping

To confirm proper draping in woven fabric, understanding the importance of cloth balance is paramount. Cloth balance, which refers to the ratio of warp to filling yarns, is essential for achieving even draping in garments.

Woven fabrics with good balance are frequently used because they prevent issues like fabric distortion and uneven stretching. Fabrics that are well-balanced with yarns in one direction offer better shape retention and are easier to work with during garment construction.

Adjusting cloth balance guarantees that the fabric drapes nicely on the body, creating aesthetically pleasing clothing items. Mastering the concept of cloth balance within woven fabrics is vital for achieving the desired look and fit in garments.

Enhancing Garment Durability

Enhancing garment durability through proper cloth balance is essential for long-lasting woven fabric products.

- Maintaining balance prevents yarn slippage, ensuring the fabric's integrity.

- Similar warp and filling yarns create a stable fabric structure, enhancing strength.

- Products like shirts and towels benefit from balanced fabric to withstand wear and tear.

- Correct warp to filling yarn ratio is vital for overall garment quality and longevity.

Balanced fabric not only improves the durability of woven garments but also enhances their overall quality. By ensuring that warp and filling yarns are in harmony, the fabric becomes more resistant to damage, making it a smart choice for long-lasting and reliable products.

Understanding Selvage in Woven Fabric

Let's talk about selvage in woven fabric – it's the edge that keeps the fabric from fraying and plays an important role in maintaining its integrity.

Understanding the different types of selvages, like plain, tape, split, and lased, helps guarantee the fabric's durability and longevity.

Selvage Definition

The selvage of woven fabric, running parallel to the warp threads, provides essential stability and durability by preventing unraveling or fraying.

- Plain selvage matches the fabric design.

- Tape selvages offer strength and width.

- Split selvages are created by cutting the selvage edge and folding it under.

- Lased selvages incorporate laser technology for a clean and precise edge finish.

Understanding the different types of selvages is vital in selecting the appropriate edge finish for various woven fabric applications. The selvage not only adds structural integrity to the fabric but also contributes to the overall aesthetics and functionality. By grasping the significance of selvages, one can make informed decisions when working with woven textiles.

Selvage Importance

Understanding the importance of selvage in woven fabric is essential for ensuring durability and quality in textile products. Selvage, the self-finished edge of the fabric, plays a critical role in preventing fraying and maintaining the integrity of the material. Different types of selvages, such as plain, tape, split, and lased, offer specific benefits tailored to various product needs. Here's a breakdown of the different selvage types:

| Selvage Type | Description | Purpose |

|---|---|---|

| Plain | Matches fabric design | Ensures seamless integration |

| Tape | Adds strength & width | Provides extra durability |

| Split | Suitable for narrow items | Ideal for products like towels |

| Lased | Heat-sealed for synthetics | Ensures secure finish for synthetic fibers |

Understanding these selvage variations is critical for selecting the right type to enhance the quality and longevity of woven fabric products.

Selvage Quality

With selvage quality being a critical factor in woven fabric durability, understanding its significance is key to ensuring product longevity and integrity.

- Plain Selvages: Match the fabric design, emphasizing aesthetic appeal while offering durability.

- Tape Selvages: Provide additional strength and width, enhancing the overall stability of the fabric.

- Split Selvages: Ideal for narrow items like towels, offering a tailored finish that complements the product's purpose.

- Lased Selvages: Heat-sealed edges suitable for synthetic fibers, ensuring a clean and secure finish to prevent unraveling.

Understanding the different types of selvages and their unique characteristics is essential for evaluating the durability and finish of woven fabrics, ultimately impacting the quality and longevity of the final product.

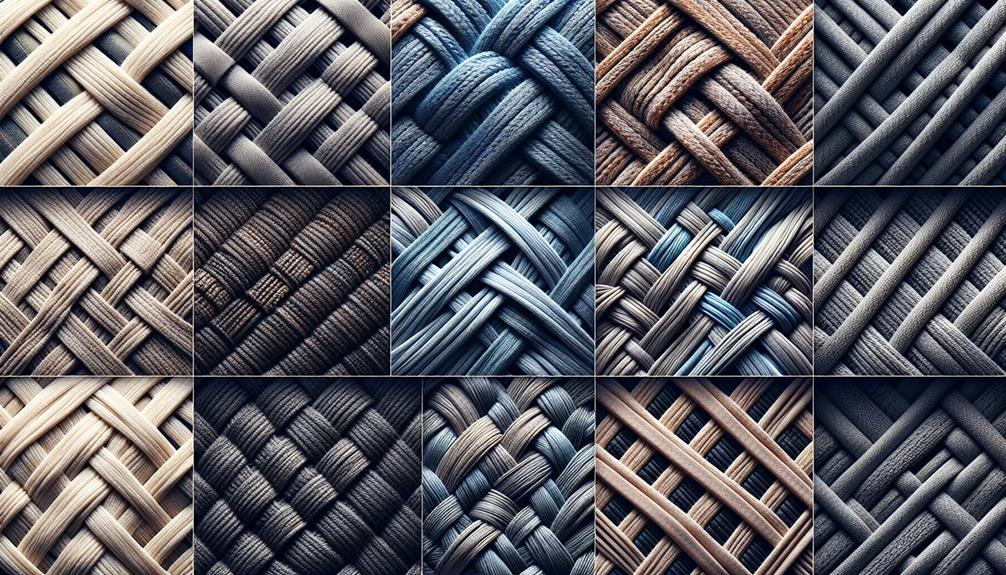

Texture and Hand Feel

When exploring the texture and hand feel of woven fabrics, one immediately notices the intricate interplay of yarn type, weave structure, and finishing techniques. Woven fabrics derive their distinct texture from the way warp and weft yarns interlace. This interlacing creates various patterns like twill, satin, or plain weaves, each impacting the tactile sensation differently.

Additionally, the hand feel of woven fabrics is further influenced by finishing treatments such as brushing, sanding, or embossing. These processes can modify the fabric's texture, making it smoother, softer, or even more textured.

The texture and hand feel of woven fabrics play an important role in their aesthetic appeal and comfort across different applications. Understanding how yarns, weaves, and finishes work together to create these sensory experiences is key to appreciating the quality and versatility of woven fabrics.

Durability and Longevity

Woven fabrics stand out for their remarkable durability and long-lasting qualities.

The tightly woven threads create a robust structure that can withstand everyday wear and tear.

This resilience translates into a longer lifespan, ensuring high quality and lasting performance in various applications.

Strength and Resilience

The robust construction of woven fabrics guarantees their durability and longevity, making them ideal for a variety of applications. Here are four key points highlighting the strength and resilience of woven fabrics:

- Tightly Bonded Threads: The tightly bonded threads in woven fabrics contribute notably to their strength, ensuring they're suitable for long-term use.

- Maintained Structural Integrity: Woven fabrics maintain their structural integrity over time, standing strong against wear and tear due to their robust construction.

- Resistance to Stretching: The strong interlacing of warp and weft threads in woven fabrics enhances their resistance to stretching and deformation, adding to their durability.

- Relied Upon by Industries: Industries trust the strength and resilience of woven fabrics for applications that demand enduring and reliable materials, showcasing their importance in various sectors.

Wear and Tear

With their proven strength and resilience, woven fabrics excel in withstanding wear and tear, displaying remarkable durability and longevity. The tightly bonded threads in woven fabrics create a sturdy structure that resists damage, making them ideal for long-term use.

Their tight weave design not only enhances aesthetics but also contributes to their ability to endure repeated washing and wear without significant deterioration. The interlocking yarns within woven fabrics play an important role in their strength and prevent fraying over time.

Proper care guarantees that woven fabrics maintain their integrity, retaining their structural strength and resistance to wear and tear. This durability makes woven fabrics a reliable choice for those seeking long-lasting and resilient textiles.

Lifespan and Quality

Quality woven fabrics boast impressive durability and longevity, standing the test of time with proper care and maintenance. When considering the lifespan and quality of woven fabrics, it's essential to understand the following:

- Influencing Factors: The durability of woven fabric is affected by the type of fibers used, the weave structure, and how well it's maintained.

- Longevity: High-quality woven fabrics have the potential to last for years, maintaining their original appearance and texture.

- Resistance to Wear: The durability inherent in woven fabrics ensures they can withstand regular use without showing signs of wear and tear easily.

- Investment Value: Investing in premium woven fabrics can lead to the creation of garments and textiles that remain sturdy and reliable over an extended period.

Breathability and Comfort

Breathability and comfort are key features of woven fabrics, making them a popular choice for clothing and bedding. Woven fabrics excel in allowing air circulation due to their interlaced structure. This breathability is enhanced by the flat surface of woven fabrics, reducing skin irritation and promoting airflow. Natural fibers like cotton and linen, commonly found in woven fabrics, further enhance breathability by keeping the wearer cool. Additionally, the moisture-absorbing properties of woven fabrics help in wicking away sweat, contributing to overall comfort. These characteristics make woven fabrics a preferred choice for various applications where breathability and comfort are essential.

| Breathability | Comfort |

|---|---|

| Interlaced structure allowing air circulation | Reduces skin irritation |

| Flat surface enhances airflow | Promotes breathability |

| Natural fibers like cotton and linen enhance breathability | Moisture-absorbing properties |

| Helps in wicking away sweat | Preferred for clothing and bedding |

Drape and Fluidity

To achieve elegant garment silhouettes and graceful movement, understanding the drape and fluidity of woven fabrics is essential. When it comes to woven fabrics, how they hang and flow is critical for creating beautiful designs.

Here are some key points to take into account:

- Weave Type: Fabrics with a loose weave tend to have better drape and fluidity, allowing them to move gracefully.

- Factors Influencing Drape: Yarn twist, yarn density, and fabric weight all play a role in determining how a fabric drapes and moves.

- Fabric Weight: Heavier fabrics with higher density often have less drape, resulting in a stiffer appearance.

- Yarn Choice: Opting for soft and lightweight yarns like silk or rayon can enhance the smoothness of the drape and fluidity in woven fabrics.

Understanding these factors is key to manipulating the behavior of woven fabrics and achieving the desired look and feel in your garments.

Printability and Design Versatility

Woven fabrics showcase exceptional printability and design versatility due to their flat surface and stable structure, allowing for a wide range of intricate designs to be effortlessly applied. The flat nature of woven fabrics provides an ideal canvas for printing, ensuring that intricate patterns and detailed motifs appear sharp and well-defined. From simple stripes to complex geometric shapes, the design possibilities with woven fabrics are vast, making them perfect for a myriad of decorative and artistic applications.

Different weaving techniques, such as jacquard and dobby, further enhance the design versatility of woven fabrics by introducing unique elements and textures. These techniques allow for the creation of intricate patterns and raised designs, adding depth and interest to the fabric. Additionally, woven fabrics can be customized using various printing methods like screen printing, digital printing, and heat transfer, offering endless opportunities for creative expression.

The printability and design versatility of woven fabrics make them highly sought after in industries such as fashion apparel, home decor, and technical textiles, where visual appeal plays an important role in the final product.

Care and Maintenance Tips

When caring for woven fabrics, it's essential to follow the fabric label care instructions diligently to maintain their quality and longevity. Here are some important care and maintenance tips for woven fabrics:

- Wash Separately: To prevent color bleeding, wash dark and light-colored woven fabrics separately. This simple step can help preserve the vibrancy of the colors and prevent unwanted staining.

- Use Mild Detergent: Opt for mild detergent and avoid harsh chemicals when washing woven fabrics. Harsh chemicals can damage the fibers and affect the fabric's overall integrity over time.

- Dry Carefully: After washing, dry woven fabrics flat or hang them to prevent stretching and distortion. Proper drying techniques can help maintain the fabric's shape and structure.

- Store Wisely: Store woven fabrics in a cool, dry place away from direct sunlight. This practice can help prevent fading and damage, ensuring your fabrics stay in top condition for longer periods.

Environmental Impact and Sustainability

Considering the environmental impact of woven fabrics is essential for promoting sustainability in the textile industry. Woven fabrics can have a significant ecological footprint due to resource-intensive production processes and chemical treatments. To address this, sustainable practices such as using organic or recycled fibers, reducing water and energy consumption, and implementing eco-friendly dyeing methods are vital in mitigating the environmental consequences of woven fabric production.

The textile industry's contribution to water pollution and waste generation underscores the need for a shift towards sustainable manufacturing practices in woven fabric production. Exploring innovations like eco-friendly fibers, biodegradable materials, and closed-loop production systems can further enhance the sustainability of woven fabric manufacturing.

As consumers, supporting sustainability in woven fabrics can be achieved by selecting products from ethical and transparent brands, advocating for circular fashion initiatives, and prolonging the lifespan of textiles through proper care and maintenance. Embracing these sustainable approaches is pivotal for reducing the environmental impact of woven fabrics and fostering a more eco-conscious textile industry.

Frequently Asked Questions

What Makes a Fabric Woven?

Creating woven fabric involves interlacing warp and weft yarns on a loom, forming a stable structure. This process imparts strength and flexibility to the fabric. The distinct patterns like plain, twill, or satin weaves are achieved through weaving techniques.

What Are the Basic Elements of Woven Fabric?

In woven fabric, the warp and weft yarns are key. The warp runs lengthwise, weft widthwise. Their interlacing creates the fabric's structure. This interaction forms the grid pattern and gives woven fabrics strength, stability, and dimension.

How Do You Identify Woven Fabric?

I spot woven fabric by its distinct front and back sides. It lacks stretch on the bias and tends to fray when cut. The weaving technique yields a stable, less stretchy material. These traits differentiate it from knits.

What Are the Basic Characteristics Differences Between Knitted Fabrics and Woven Fabrics?

When comparing knitted and woven fabrics, it is crucial to note that knits offer more stretch and texture, great for activewear like jersey. Wovens are less stretchy, ideal for structured items such as denim. Understanding these differences is key.