Yes, I can confirm that nylon can be recycled! It's actually quite impressive how they reuse post-industrial waste, old carpets, and even fishing nets to create new nylon products. They do this by collecting the old nylon, cleaning it thoroughly, shredding it into small pieces, and then melting those pieces to form new pellets. This whole process helps conserve resources, reduce greenhouse gases, and minimize plastic waste by promoting a circular economy. There's a lot more about the process that shows how it's beneficial, and I think you'll find the deeper insights pretty fascinating.

Key Takeaways

- Nylon can be recycled through mechanical processes, which involve shredding, melting, and reforming into new products.

- Chemical depolymerization methods break down nylon into its basic components for remanufacturing.

- Recycled nylon helps conserve resources, reduce greenhouse gases, and minimize plastic waste.

- The recycling process includes collection, cleaning, shredding, and regeneration of nylon waste.

- Challenges such as high costs, contamination, and technological demands need addressing to enhance recycling efficiency.

Understanding Nylon Recycling

While nylon recycling involves complex processes, it essentially breaks down old materials to create something new and sustainable. By unraveling used nylon into its chemical components, the stage is set to reforge these into fresh nylon sheets and fibers. It's a smart way to tackle waste, turning what could be trash into valuable resources again.

Recycling nylon significantly slashes the environmental impact associated with material disposal. Instead of clogging up landfills, recycled nylon gets a second life in various products, ranging from clothing to industrial goods. This not only helps keep our planet cleaner but also conserves resources by reducing the need for new raw materials.

The process feeds into a circular economy, where nothing is wasted and everything is reused. It's an ideal that companies like Patagonia and Outerknown are already putting into practice, proving that recycled nylon isn't just a concept but a practical, workable solution. By supporting products made with recycled nylon, we're part of a movement towards sustainability, making a tangible difference in minimizing our environmental footprint. It's about being smart with our resources and thinking ahead for the sake of our planet.

Types of Recyclable Nylon

Let's explore the different types of recyclable nylon, which include not only post-industrial waste but also items like fishing nets and old carpets. Delving into the world of nylon recycling opens up a surprising array of materials that can be transformed into valuable recycled nylon. It's fascinating how materials once deemed as waste are now pivotal in sustainable manufacturing.

Here's a quick rundown of the main categories:

- Post-Industrial Waste: This includes scraps from nylon production which are then processed back into usable forms.

- Nylon Fishing Nets: Old or damaged nylon fishing nets are collected and regenerated into new nylon fibers.

- Old Carpets: Yes, even your worn-out carpets can lead a new life as part of recyclable nylon products.

- Econyl: This brand has become synonymous with sustainability by turning waste like fishing nets and fabric scraps into high-quality recycled nylon.

Understanding these types feeds into a larger conversation about sustainability. Each type of recyclable nylon contributes to reducing plastic waste, thereby benefiting our environment significantly. Whether it's in fashion or interior design, these recycled materials are proving that green solutions can be both practical and trendy.

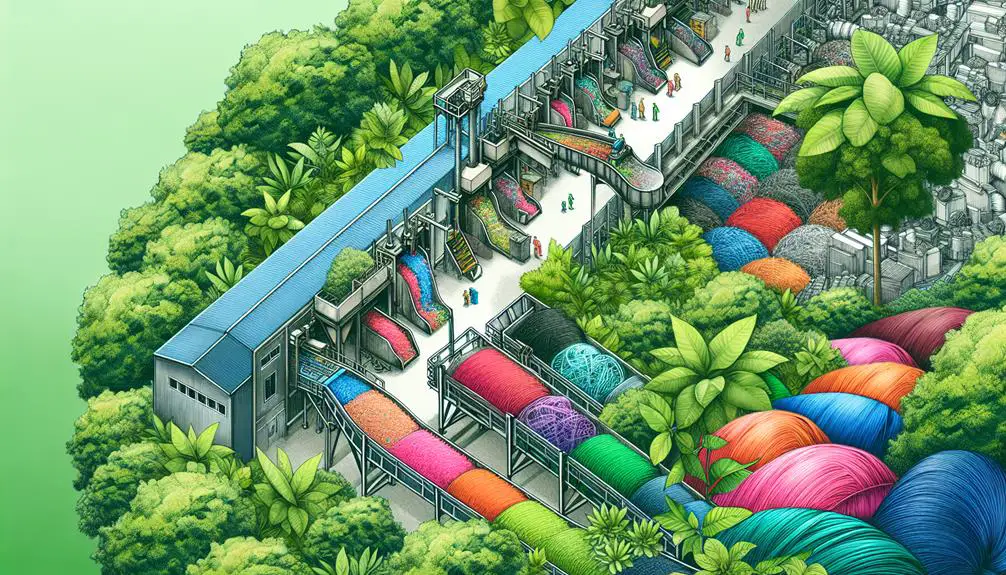

The Nylon Recycling Process

Understanding the nylon recycling process starts with collecting discarded items like fishing nets and fabric scraps. Once we've gathered enough of these old nylon products, they're ready for the next step: transformation.

The collected items are first cleaned thoroughly because, let's face it, nobody wants dirty old materials messing up their new environmentally friendly products. Then, these cleaned materials are shredded into small pieces. It's kind of like how a paper shredder works, but for nylon!

Next, these shreds are melted down. This part is pretty cool because you see all these scraps turning into something like little plastic pellets or chips. Think of them as the building blocks for new nylon products.

Here's a quick breakdown in a table:

| Step | Description | Outcome |

|---|---|---|

| Collection | Gathering fishing nets, fabric scraps | Ready materials |

| Cleaning | Removing contaminants | Clean nylon scraps |

| Shredding | Breaking down into smaller pieces | Shreds ready for melting |

| Melting | Heating shreds to form pellets | Pellets for new products |

Benefits of Recycling Nylon

Now that we've seen how nylon is recycled, let's explore the significant benefits this process brings to both our environment and economy. When we delve into the world of recycled nylon, we're not just talking about reusing old material; we're actively participating in a movement towards environmental sustainability.

Here are the core advantages:

- Conservation of Resources: Recycling nylon helps conserve non-renewable resources. Instead of producing new nylon, we repurpose what's already there, significantly reducing the need for raw materials.

- Reduction of Greenhouse Gases: Every bit of recycled nylon contributes to less energy consumption. This, in turn, lowers greenhouse gas emissions compared to producing new nylon, aligning with global efforts to combat climate change.

- Minimizing Plastic Waste: By recycling nylon products, we divert massive amounts of plastic waste from landfills and oceans. This not only cleans up our environment but also tackles the issue of plastic pollution head-on.

- Promoting Circular Economy: The cycle of making, using, and recycling nylon fosters a more sustainable economic model. It's all about keeping resources in use for as long as possible and maximizing their value.

Recycling nylon isn't just an environmental act; it's a robust step towards a sustainable future.

Challenges in Nylon Recycling

While recycling nylon offers numerous benefits, it also faces significant challenges that can hinder its effectiveness. Let's dive into the hurdles, shall we?

First up, it's all about the money. Recycling nylon isn't exactly wallet-friendly due to the complex process involved. It's a meticulous and costly endeavor that can deter companies from choosing recycled nylon over cheaper alternatives like polyethylene terephthalate (PET).

Contamination is another big issue. Getting nylon completely clean for the recycling process is tougher than you might think. This makes it tricky to maintain the quality and properties of nylon, which are essential for its performance in new products.

Because of these challenges, the idea of a circular economy really comes into play. It's seen as a promising way to make recycling nylon more viable. By designing products and systems with reuse in mind, we can potentially offset the high costs and contamination issues. Implementing circular economy models could be the key to improving the recycling loop for materials like nylon, making it not just more sustainable but also more economically feasible.

Nylon Recycling Technologies

Moving on from the hurdles, let's talk about how we can recycle nylon.

We've got mechanical recycling processes where nylon waste is physically broken down and reformed, and chemical depolymerization methods that break nylon down to its chemical building blocks to make something new. But scaling these up to industrial levels presents its own set of challenges.

Mechanical Recycling Process

Shredding nylon waste into small pieces marks the first step in mechanical recycling, a process that transforms old nylon into reusable materials. Here's how it works:

- Shred the Nylon:

First, I collect and shred used nylon products into smaller fragments.

- Melt and Reform:

These pieces are then melted down and reformed into pellets or chips.

- Manufacture New Products:

These pellets are used to create various new nylon products, effectively recycling the material.

- Reduce Energy Use:

By choosing to recycle nylon through mechanical recycling, I actively help reduce energy consumption and greenhouse gas emissions compared to producing new nylon.

It's a straightforward yet effective way to keep nylon in use and out of landfills!

Chemical Depolymerization Methods

How does chemical depolymerization turn old nylon into new materials? Well, it's all about breaking down those long chains of nylon molecules into their basic components. This method doesn't just chop them up randomly; it strategically dismantles them so they can be rebuilt into fresh nylon. It's like magic, but with chemistry!

Here's a quick table to visualize the process:

| Step | Process | Outcome |

|---|---|---|

| 1. Collect | Gather nylon waste | Ready materials for processing |

| 2. Break | Apply chemical depolymerization | Nylon is reduced to basic units |

| 3. Purify | Clean the depolymerized components | Ensure purity for high-quality |

| 4. Reprocess | Reconstruct new nylon material | Create sustainable products |

This method helps us make full use of existing materials and significantly cuts down on the environmental impact of new nylon production. It's a win for sustainability!

Industrial Scale Challenges

While nylon recycling offers substantial environmental benefits, scaling up these technologies faces several significant challenges. Here's a quick rundown of the main hurdles:

- Complex Separation: Separating nylon from other materials in mixed waste is complex and often inefficient.

- Chemical Recycling Costs: Advanced methods like chemical recycling are promising but come with high costs and technological demands.

- Contamination Issues: Contaminated nylon can disrupt the recycling process, requiring additional resources to manage.

- Mechanical Recycling Limits: Repeated mechanical recycling can degrade nylon's quality, limiting its reuse potential.

Overcoming these industrial scale challenges requires collaboration across sectors. It's no small feat, but with focused efforts, we can make large-scale nylon recycling a reality.

Nylon in Sustainable Fashion

Sustainable fashion brands are increasingly turning to recycled nylon to lessen their environmental footprint. They're using it in everything from swimwear to outerwear, making big waves with eco-friendly alternatives. It's not just about looking good; it's about doing good too.

The buzz around recycled nylon has caught on largely due to the shift in what we, as consumers, demand. We're looking for brands that align with our values, ones that are not just about profit but about protecting our planet. The rise of textile recycling technologies has made this shift possible, offering us versatile and durable fabrics that don't skimp on style or sustainability.

Here's a quick look at how recycled nylon is making an impact in sustainable fashion:

| Use Case | Benefit | Example |

|---|---|---|

| Swimwear | Reduces water pollution | Eco-friendly brands |

| Activewear | Lowers fabric waste | Popular sportswear |

| Outerwear | Saves energy | Innovative jackets |

| Consumer demand | Boosts brand image | Trendy collections |

| Technology | Enhances fabric quality | Advanced materials |

Lifecycle of Recycled Nylon

When we talk about recycling nylon, it starts with collecting and sorting old nylon products.

Next, these materials undergo a regeneration process where they're broken down chemically and made into new nylon.

It's fascinating to see how this process not only keeps nylon out of landfills but also lessens our environmental footprint.

Collection and Sorting Processes

To kick off the recycling journey, discarded nylon products like fishing nets and fabric scraps are first collected and sorted. This step is crucial for setting up efficient recycling processes and transforming waste effectively. Here's how it goes down:

- Gather Up: Collection teams round up nylon waste from various sources, including old fishing nets that harm marine life when left in the ocean.

- Sort Out: The collected nylon is then sorted by material type, color, and condition. This ensures that only suitable materials make it through.

- Clean Up: Before anything else, the sorted nylon waste must be cleaned. It's about prepping it right!

- Shred to Threads: Finally, the clean nylon is shredded into fibers, ready for the next phase of its recycled life.

This whole process makes sure we're set up for success in creating new, sustainable products!

Regeneration and Remanufacturing Steps

After the initial sorting and cleaning, the real magic happens as we break down nylon waste into its chemical components. This part of the manufacturing process, known as regeneration, is crucial. We're not just recycling; we're essentially giving these materials a new lease on life.

The broken-down components are then recombined and transformed into nylon sheets. These sheets are heated and spun back into nylon fibers, ready to be woven into recycled nylon fabric.

This remanufacturing step mirrors the process used for virgin nylon but with a sustainable twist. The entire cycle, from fiber spinning to fabric weaving, ensures that every bit of nylon gets a second chance at usefulness, closing the loop in the lifecycle of recycled nylon.

Environmental Impact Assessment

Assessing the environmental impact of recycled nylon reveals significant benefits, from reduced energy use to lower greenhouse gas emissions. Here's a concise rundown:

- Energy and Emissions: Recycling nylon cuts down on the energy required and significantly reduces greenhouse gas emissions compared to making virgin nylon.

- Waste Reduction: It keeps a lot of plastic waste out of our oceans and landfills.

- Resource Conservation: Using existing nylon waste saves non-renewable resources, which is a win for our planet.

- Sustainable Practice: Promotes a circular economy, making our fabrics more sustainable.

Understanding these points helps us see why recycled nylon isn't just an option but a necessity for a cleaner, more sustainable future.

Comparing Recycled and Virgin Nylon

Choosing recycled nylon over virgin nylon significantly cuts down on both energy use and greenhouse gas emissions. Let's dive into why that's the case. Recycled nylon slashes energy consumption by up to 50% compared to its virgin counterpart. That's a massive saving! Plus, it emits 57% fewer greenhouse gases. Think about it—that's over half the pollutants not entering our atmosphere.

Here's a quick breakdown in a simple table to see the stark differences:

| Aspect | Recycled Nylon | Virgin Nylon |

|---|---|---|

| Energy Consumption Reduction | Up to 50% less | – |

| Greenhouse Gas Emissions | 57% fewer emissions | – |

| Oil Conservation (barrels) | Over 420,000 annually | Requires 380,000 daily |

Choosing recycled materials isn't just about feeling good; it's about concrete benefits. By opting for recycled nylon, we divert over 10,000 tons of waste from landfills each year. Plus, considering the staggering amount of oil needed for virgin nylon, the choice seems obvious. Why demand more oil when we can reuse what we've already got? Every choice towards recycled nylon is a step towards a more sustainable planet. Let's make it count!

Future of Nylon Recycling

Looking ahead, the future of nylon recycling is pretty exciting.

We're seeing groundbreaking recycling technologies that not only lessen environmental impacts but also open up new market opportunities.

It's all about making the industry more sustainable and economically viable.

Innovative Recycling Technologies

Exploring innovative recycling technologies reveals how companies like Aquafil are transforming discarded nylon into premium products. They're not just recycling; they're revolutionizing the way we think about sustainability and product lifecycle.

Here's how this exciting field is evolving:

- Aquafil's Econyl Process: Converts waste like nylon fishing nets into high-quality thread, making recycled nylon that rivals virgin quality.

- Bureo's Creative Approach: Turns old fishing nets into cool skateboards and sunglasses, showing recycled products can be both functional and stylish.

- Patagonia's Commitment: Uses recycled nylon in over 50 different products, pushing the market towards sustainable options.

- Technological Advancements: Focus on improving the quality and efficiency of recycling processes to ensure recycled nylon meets top industry standards.

Environmental Impact Reduction

Building on innovative technologies like Aquafil's Econyl process, focusing on the future of nylon recycling is key to reducing environmental impacts. By ramping up the use of recycled nylon, we're not just cutting down on energy use and emissions; we're also tackling the mountain of plastic waste. Here's a quick snapshot:

| Benefit | Description | Impact on Sustainability |

|---|---|---|

| Energy Reduction | Less energy compared to virgin nylon production | High |

| Waste Diversion | Plastic waste moves from oceans to use | Critical |

| Resource Conservation | Saves non-renewable resources | Essential |

Embracing a circular economy isn't just good practice; it's a necessity for sustainability. We're on a track to make a significant difference.

Market Growth Prospects

The recycled nylon market is set to grow significantly, driven by an increasing demand for eco-friendly materials and sustainable fashion. Here's what's fueling this trend:

- Technological Innovations: Advances in recycling processes are making it easier and more efficient to produce high-quality recycled nylon.

- Brand Collaborations: More brands are teaming up with recycling facilities and taking part in government initiatives, creating a stronger market.

- Consumer Awareness: People are more informed about environmental issues and are choosing products made from recycled materials.

- Sustainable Fashion Demand: As the push for sustainability in fashion grows, so does the need for materials that meet these values.

It's clear that the future looks bright for recycled nylon!

Frequently Asked Questions

Why Is Nylon Not Recyclable?

Nylon's not easily recyclable because its complex chemical makeup and contamination issues make it tough and costly to process. Most recyclers prefer simpler, more economical options like PET.

How Can We Recycle Nylon?

To recycle nylon, it's broken down chemically and then reconstructed into new material. Companies like Aquafil are leading this, making it crucial to support products made from recycled nylon for sustainability.

Is Nylon 100% Recyclable?

Yes, nylon is 100% recyclable, though the process is complex. Products like Econyl reuse waste nylon to create new fibers, helping brands like Patagonia reduce environmental impact and promote a circular economy.

Is Recycled Nylon Actually Sustainable?

Yes, recycled nylon is sustainable. It cuts energy use, reduces emissions, and conserves resources. Plus, it supports a circular economy by turning waste into useful material, aligning with eco-conscious consumer preferences.