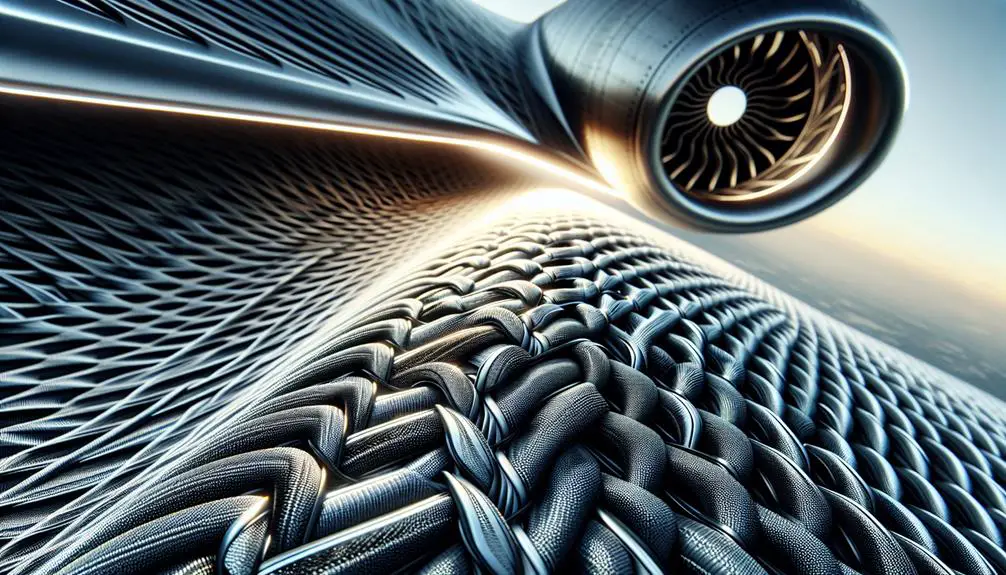

Imagine a world where the fabric of the sky itself is woven with threads of technological marvels. When you think about aerospace fabrics, you're entering a domain where materials like carbon fiber and Kevlar aren't just futuristic—they're essential. These high-performance fabrics are designed to withstand extreme conditions, from searing temperatures to intense radiation. The science behind these materials isn't just fascinating; it's critical for the safety and efficiency of modern aircraft and spacecraft. So, how do these fabrics transform ordinary components into extraordinary aerospace solutions? Let's explore this intriguing intersection of material science and aerospace innovation.

Table of Contents

Key Takeaways

- Composite fibers like carbon fiber and Kevlar enhance strength and reduce weight in aerospace applications.

- Advanced thermal insulation fabrics withstand extreme temperatures and maintain structural integrity.

- High-performance materials are engineered for durability, flexibility, and resistance to harsh environmental conditions.

- Innovations include self-healing materials, recyclable fabrics, and advanced coatings for improved performance.

- Lightweight aerospace fabrics contribute to enhanced fuel efficiency and reduced environmental impact.

The Role of Aerospace Fabrics

Aerospace fabrics play an important role in guaranteeing the safety, durability, and performance of aircraft and spacecraft. Their significance stems from constant material advancements and rigorous research developments, which drive the industry forward.

By staying on the cutting edge of technology, you can make sure that aerospace fabrics meet the demanding conditions they face. To achieve this, it's essential to understand the latest industry trends and how they influence fabric performance.

Keeping up with these trends means you'll be familiar with innovations like lighter, stronger materials that enhance fuel efficiency and reduce wear and tear. Research developments continually push the boundaries of what's possible, leading to fabrics that can withstand extreme temperatures, resist radiation, and maintain their integrity under mechanical stress.

In aerospace, there's no room for compromise—every material must perform at its best.

Key Characteristics

Understanding the key characteristics of aerospace fabrics is essential for ensuring they perform efficiently in the harsh environments they encounter. You need materials that stand up to extreme conditions, and that's where durability comes into play. Aerospace fabrics must endure significant wear and tear without compromising their structural integrity. This durability ensures that the materials can withstand the rigors of space travel and prolonged exposure to adverse conditions.

Flexibility is another crucial trait. The dynamic nature of aerospace applications demands fabrics that can adapt to various shapes and movements without losing their strength. Flexible materials are essential for components like deployable structures and protective coverings, where rigidity could be a disadvantage.

Temperature resistance is equally important. Aerospace fabrics face extreme temperatures, from the intense heat during re-entry to the freezing cold of outer space. High-performance materials need to maintain their properties and functionality across this wide temperature range to protect both equipment and crew.

Types of Aerospace Fabrics

When exploring types of aerospace fabrics, you'll encounter composite fiber components and thermal insulation fabrics.

Composite fibers offer strength and flexibility, making them ideal for aircraft structures.

Thermal insulation fabrics protect against extreme temperatures, ensuring the safety and performance of aerospace systems.

Composite Fiber Components

In modern aerospace engineering, composite fiber components like carbon fiber, Kevlar, and fiberglass have revolutionized the design and performance of aircraft. These materials offer unparalleled benefits in terms of weight reduction and strength.

Carbon fiber, recognized for its high strength-to-weight ratio, provides exceptional fiber reinforcement, thereby enhancing the structural integrity of the aircraft.

Kevlar, another high-performance material, is renowned for its impact resistance and durability, making it ideal for critical components that must endure extreme conditions.

When you consider material compatibility and advanced technology, fiberglass stands out as a versatile and cost-effective option. Its ability to blend seamlessly with other materials ensures that you can achieve optimal performance without compromising on weight or strength.

Advanced manufacturing techniques, such as resin transfer molding and automated fiber placement, allow for the precise integration of these materials into complex aerospace structures.

Thermal Insulation Fabrics

Thermal insulation fabrics in aerospace applications play an important role in maintaining ideal temperature control and protecting sensitive components. These fabrics excel in environments with extreme temperature fluctuations, ensuring that you achieve both safety and efficiency in your projects. The material composition and performance of these fabrics are vital; they often incorporate advanced polymers, ceramics, and metallic fibers to offer superior thermal resistance, durability, and lightweight properties.

Advancements in this field have greatly impacted the industry. Innovations like aerogel-infused fabrics and high-performance ceramic composites have elevated the standards. These materials not only enhance performance but also contribute to weight reduction, a key factor in aerospace design.

Here's a detailed look at some common thermal insulation fabrics:

| Fabric Type | Key Properties |

|---|---|

| Aerogel-Infused Fabrics | Ultra-lightweight, high thermal resistance |

| Ceramic Composites | Exceptional heat tolerance, durability |

| Metallic Foil Laminates | Reflective, strong thermal insulation |

| High-Performance Polymers | Lightweight, versatile thermal barrier |

Manufacturing Techniques

Mastering the manufacturing techniques for aerospace fabrics guarantees you achieve the highest performance and durability in demanding conditions. To begin with, understanding the various weaving methods is pivotal. These methods, such as plain weave, twill, and satin, directly influence the material properties of your fabrics.

For instance, a plain weave provides a balanced strength-to-weight ratio, while twill offers better drapability and durability.

Next, you'll need to focus on material properties. Selecting high-performance fibers like carbon, aramid, or glass secures your fabric withstands extreme temperatures and mechanical stresses. Each fiber type has unique characteristics: carbon fibers are recognized for their high strength-to-weight ratio, aramid fibers excel in impact resistance, and glass fibers provide excellent thermal stability.

Incorporating advanced finishing techniques is also necessary. Surface treatments like resin impregnation, flame retardation, and coating applications enhance the fabric's overall performance. These processes not only enhance resistance to environmental factors but also prolong the fabric's lifespan.

Applications in Aircraft

When it comes to aircraft, aerospace fabrics play a critical role in guaranteeing structural integrity and passenger safety. These high-performance materials are integral to both aircraft interiors and exterior coatings, offering durability and enhanced performance while maintaining lightweight properties.

In aircraft interiors, fabrics are used for seating, carpeting, and insulation. They're designed to withstand high stress, resist fire, and provide comfort. Advanced textile technologies make sure that the interiors are not only aesthetically pleasing but also functional and safe. For exterior coatings, aerospace fabrics contribute to the aerodynamic efficiency and protection against environmental factors like UV radiation and moisture.

Here's a comparison highlighting the key aspects of aerospace fabrics in aircraft applications:

| Feature | Aircraft Interiors | Exterior Coatings |

|---|---|---|

| Durability | High | Extremely High |

| Fire Resistance | Essential | Not Primary |

| Weight | Lightweight | Ultralight |

| Aesthetic Importance | High | Low |

| Environmental Protection | Moderate | Essential |

Spacecraft Uses

In spacecraft, aerospace fabrics are indispensable for maintaining thermal insulation and shielding against harsh environmental conditions. When you're involved in spacecraft design, these high-performance materials become your go-to for preserving the integrity and functionality of space vehicles.

Aerospace fabrics are critical in the construction of space stations, where they provide protection from micrometeoroid impacts and extreme temperature fluctuations. These fabrics are engineered to withstand the vacuum of space while also offering flexibility and durability.

When it comes to satellite deployment, aerospace fabrics play a pivotal role. They're used in the construction of deployable structures such as solar sails and antennas. These materials optimize that the components remain lightweight yet robust, facilitating ease of deployment and operational reliability.

For instance, materials like Kevlar and Nextel are commonly used in multi-layer insulation blankets, which keep the satellite's instruments at peak temperatures.

Heat Resistance

When considering aerospace fabrics, you'll need to understand their thermal shielding capabilities. These fabrics must endure extreme temperatures, so knowing their temperature tolerance limits is important.

Let's explore how these materials protect spacecraft and guarantee mission success.

Thermal Shielding Capabilities

Boasting exceptional heat resistance, aerospace fabrics play a pivotal role in thermal shielding for high-temperature environments. When you're dealing with extreme temperatures, the material composition of these fabrics is essential. Advanced fibers like aramid and carbon are specifically engineered to maintain structural integrity and protect essential components. The unique blend of these materials guarantees that the fabrics can withstand the most rigorous conditions without compromising performance.

In the domain of space exploration, protective textiles are indispensable. Imagine a spacecraft re-entering Earth's atmosphere; the exterior is exposed to temperatures that can soar above 3,000 degrees Fahrenheit. Here, the thermal shielding capabilities of aerospace fabrics make all the difference. They act as a barrier, preventing the intense heat from penetrating and damaging critical systems.

Engineers and material scientists continuously innovate, working to enhance these fabrics' thermal performance. They combine cutting-edge technology with rigorous testing to push the limits of what's possible.

For you, mastering the complexities of aerospace fabrics means understanding how these high-performance materials serve as the frontline defense against extreme thermal conditions, ensuring the safety and success of missions in the most unforgiving environments.

Temperature Tolerance Limits

Understanding the temperature tolerance limits of aerospace fabrics is essential for ensuring their reliability in high-heat situations. You need to know how these materials perform under extreme conditions to make informed decisions about their applications.

High-performance aerospace fabrics must deliver exceptional heat protection while maintaining structural integrity.

When evaluating the thermal performance of these fabrics, consider the following key factors:

- Maximum Operating Temperature: Determine the highest temperature the fabric can withstand without degrading. This is vital for applications in both aircraft and spacecraft, where extreme heat is common.

- Thermal Conductivity: Understand how well the fabric can conduct heat. Materials with low thermal conductivity are better at insulating, providing superior heat protection.

- Decomposition Temperature: Identify the point at which the fabric breaks down chemically. This helps you anticipate material failure in severe heat environments.

- Thermal Expansion: Assess how much the fabric expands when heated. Materials with low thermal expansion maintain their shape and functionality under thermal stress.

Lightweight Benefits

Lightweight aerospace textiles significantly enhance fuel efficiency and overall performance. By focusing on weight reduction, these advanced materials enable aircraft to fly farther on less fuel, leading to cost savings and a diminished environmental impact. The performance improvement achieved through lighter textiles is substantial, as it can result in faster takeoffs, smoother flights, and improved maneuverability. These textiles are crafted with precision, ensuring that every gram saved contributes to the overall efficiency of the aircraft.

Innovation in aerospace textiles doesn't just stop at making things lighter; it also embraces sustainability. The development of these materials often involves the use of eco-friendly processes and renewable resources. By prioritizing sustainable practices, you help guarantee that the aerospace industry can continue to thrive without compromising the planet's health.

Incorporating lightweight aerospace textiles into your designs means you're not just keeping up with industry standards – you're setting them. Mastering the application of these materials can position you at the forefront of aviation technology, where performance and sustainability go hand in hand. So, invest in these high-performance textiles to elevate your projects to new heights.

Strength and Durability

Aerospace textiles are engineered to deliver exceptional strength and durability, guaranteeing that aircraft can withstand extreme conditions. To achieve this, these textiles undergo rigorous material testing and performance evaluation.

You need to understand that these evaluations are vital for validating the textiles' ability to perform under various environmental conditions and stress testing scenarios.

Here's a closer look at the key aspects involved:

- Material Testing: Advanced techniques like tensile strength tests and fatigue resistance evaluations ensure that the textiles can handle immense pressures and repetitive loading.

- Performance Evaluation: This involves assessing the fabric's behavior under real-world conditions to ensure it meets stringent aerospace standards.

- Environmental Conditions: Fabrics are exposed to extreme temperatures, humidity, and UV radiation to replicate the harsh environments they'll encounter in flight.

- Stress Testing: By applying mechanical stress, engineers can determine the fabric's breaking point and guarantee it exceeds the necessary safety margins.

You'll find that these rigorous tests are essential, providing confidence in the fabric's resilience and reliability. Mastering the intricacies of aerospace fabric strength and durability is crucial for pushing the boundaries of modern aviation and ensuring the safety and efficiency of aircraft.

Future Innovations

Emerging technologies promise groundbreaking advancements in aerospace fabrics, pushing the limits of what these materials can achieve. You'll see a shift towards sustainable solutions and advanced materials that minimize environmental impact while maximizing performance. Researchers are exploring nanomaterials, smart textiles, and bio-based fibers to revolutionize the aerospace industry.

These innovations not only enhance durability and strength but also offer lightweight and flexible options. Imagine fabrics that can self-heal, change properties in response to environmental conditions, or even generate energy. Such advancements could redefine the possibilities in aerospace design and function.

| Innovation | Benefit | Application |

|---|---|---|

| Nanomaterials | Enhanced strength and light weight | Structural components |

| Smart textiles | Adaptive properties | Temperature and pressure regulation |

| Bio-based fibers | Reduced environmental impact | Sustainable manufacturing |

Technological advancements in aerospace fabrics aren't just about improving performance; they're about creating a more sustainable future. By incorporating advanced materials that reduce waste and energy consumption, you help lessen the environmental impact. The future of aerospace fabrics is not just about flying higher or faster; it's about doing so responsibly and efficiently. Get ready to witness a new era where cutting-edge technology meets sustainability in the most exciting ways.

Frequently Asked Questions

How Do Aerospace Fabrics Impact Fuel Efficiency in Aviation?

You'll notice that aerospace fabrics greatly enhance fuel efficiency by contributing to weight reduction. When aircraft weigh less, they consume less fuel, which not only saves costs but also benefits the environment through reduced emissions.

What Are the Environmental Considerations for Aerospace Fabric Production?

You need to take sustainability into account in production processes and conduct a thorough environmental impact assessment. Make sure that materials are sourced responsibly and manufacturing practices minimize waste and emissions for a truly eco-friendly approach.

How Do Maintenance and Repair of Aerospace Fabrics Compare to Traditional Materials?

How do you handle maintenance challenges and repair techniques with aerospace fabrics compared to traditional materials? You'll find aerospace fabrics often require specialized tools and skills, but they offer superior durability and performance, streamlining long-term upkeep.

Are There Any Specific Regulations Governing the Use of Aerospace Fabrics?

You must guarantee regulatory compliance by adhering to industry standards. Specific regulations govern the use of these materials, and staying updated on them is vital for maintaining safety and performance. Don't overlook these essential guidelines.

How Do Aerospace Fabrics Contribute to Passenger Safety in Aircraft?

Think of aerospace fabrics as the guardian angels of the sky. They enhance passenger safety through fire resistance, impact resistance, weight reduction, and durability. You'll feel secure knowing these materials are designed to protect you.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024