You’ll find woven fabrics are made by interlacing warp and weft yarns at right angles, giving them strong, durable, and shape-retaining structures ideal for apparel and upholstery. Nonwoven fabrics, on the other hand, bond fibers mechanically or chemically, resulting in lightweight, flexible materials great for disposable or specialized uses like medical and hygiene products. Each has distinct manufacturing methods and performance traits. Keep exploring, and you’ll uncover their unique applications and sustainability impacts.

Key Takeaways

- Woven fabrics consist of interlaced warp and weft yarns at right angles, forming a stable, structured grid.

- Nonwoven fabrics bond fibers using mechanical, chemical, or thermal processes without weaving or knitting.

- Woven fabrics offer higher tensile strength and durability due to their tight, interlaced yarn structure.

- Nonwoven fabrics provide versatility in thickness and texture, suitable for disposable or specialized uses.

- Woven fabrics maintain shape with less elasticity, while nonwovens are more flexible but generally less strong.

Definition and Basic Characteristics of Woven Fabrics

Woven fabrics consist of two sets of yarns interlaced at right angles, creating a structured and durable textile.

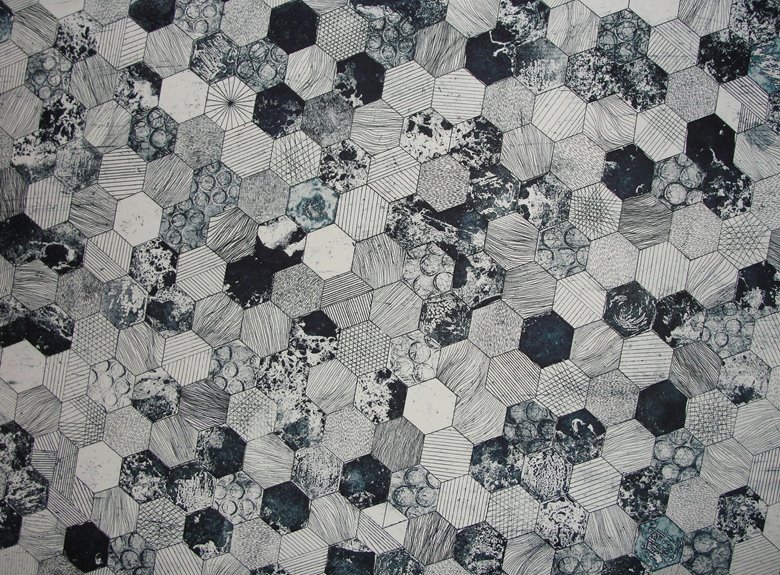

When you look at woven fabric, you’ll notice the warp yarns run lengthwise while the weft yarns run crosswise, tightly interlacing to form a grid-like pattern. This interlacing provides strength, stability, and resistance to stretching.

You’ll find woven fabrics come in various weaves like plain, twill, and satin, each affecting texture and appearance.

Because of their construction, woven fabrics hold their shape well and have good durability, making them ideal for garments, upholstery, and industrial applications.

You can expect a firm hand feel and less elasticity compared to other fabric types, which helps maintain form during use and washing.

Definition and Basic Characteristics of Nonwoven Fabrics

Nonwoven fabrics form when fibers are bonded together through mechanical, chemical, or thermal processes instead of being woven or knitted.

Nonwoven fabrics bond fibers through mechanical, chemical, or thermal methods rather than weaving or knitting.

You’ll find that these fabrics offer unique characteristics that set them apart from woven textiles. They don’t rely on interlacing yarns, which means they can be manufactured quickly and in various thicknesses and textures.

When you choose nonwoven fabrics, you benefit from:

- Lightweight and flexible material that adapts to numerous applications

- Cost-effective production allowing for disposable and durable uses

- Customizable properties like absorbency, filtration, and strength depending on bonding methods

Understanding these basics helps you appreciate nonwoven fabrics’ versatility, especially in industries like medical, hygiene, and filtration, where their unique structure is essential.

Manufacturing Processes of Woven Fabrics

You’ll find that creating fabric with interlaced yarns involves several precise steps, starting from preparing the threads to the final weaving on a loom.

First, you warp the yarns by aligning them lengthwise on the loom. Then, you prepare the weft yarns, which will cross the warp yarns horizontally.

Next, you set up the loom, ensuring proper tension and alignment. As you operate the loom, the warp yarns lift and lower alternately, allowing the weft yarn to pass through the shed created. This interlacing forms the woven fabric’s structure.

Throughout, you monitor for uniformity and correct any defects. Finally, after weaving, you proceed with finishing processes, like washing or heat-setting, to enhance fabric performance.

This method gives woven fabrics their characteristic strength and durability.

Manufacturing Processes of Nonwoven Fabrics

Although the process differs from weaving, producing fabric without interlacing yarns still involves careful steps to guarantee strength and consistency.

When you make nonwoven fabrics, you start by bonding or entangling fibers through various methods. These methods include:

- Chemical bonding, where adhesives or binders hold fibers together.

- Thermal bonding, which uses heat and pressure to fuse fibers.

- Mechanical bonding, such as needle punching or hydroentangling, physically interlocks fibers.

Each technique affects the fabric’s texture and suitability for different applications.

You’ll find nonwovens in products ranging from medical masks to geotextiles because you can tailor their properties easily.

Mechanical Properties: Strength and Durability Comparison

Understanding how fibers bond during manufacturing sets the stage for comparing the mechanical properties of woven and nonwoven fabrics.

When you look at woven fabrics, their interlaced structure provides high tensile strength and excellent durability. The tight weave distributes stress evenly, making them ideal for applications requiring long-term use and resistance to wear.

Nonwoven fabrics, on the other hand, rely on fiber entanglement or bonding, which offers decent strength but generally falls short compared to woven textiles. You’ll find nonwovens excel where lightweight and disposable properties matter more than heavy-duty strength.

However, advancements in bonding technologies have improved their durability, narrowing the gap. Ultimately, choosing between woven and nonwoven depends on how much strength and longevity your project demands.

Flexibility and Breathability Differences

While woven fabrics boast a tightly interlaced structure that often limits their flexibility, they generally allow for better breathability due to the spaces between yarns.

You’ll find woven fabrics maintain shape but feel less stretchy. Nonwoven fabrics, on the other hand, offer greater flexibility since their fibers are bonded rather than woven.

However, this can reduce airflow, making them less breathable.

Consider these points when choosing between them:

- Woven fabrics provide superior air circulation, ideal for comfort in warm conditions.

- Nonwoven fabrics excel in flexibility and conform easily to different shapes.

- Breathability in nonwovens varies considerably based on fiber bonding and thickness.

Understanding these differences helps you select the right fabric for your specific needs.

Typical Applications of Woven Fabrics

You’ll find woven fabrics everywhere, from the clothes you wear to the gear that keeps you safe on the job.

They’re also key in home furnishings like curtains and upholstery.

Let’s explore how their structure makes them ideal for these uses.

Apparel and Textiles

Because woven fabrics offer strength and durability, they’ve become a staple in apparel and textiles. When you choose woven fabrics, you’re opting for materials that hold their shape well, resist wear, and provide comfort in everyday clothing.

You’ll find them in various garments, from casual to formal wear, ensuring longevity and style.

Typical applications include:

- Shirts and blouses that maintain a crisp appearance after multiple washes

- Denim jeans that require toughness and flexibility for daily use

- Dresses and suits that benefit from the structured weave for a polished look

Industrial and Safety Gear

Woven fabrics serve as the backbone for many types of industrial and safety gear, thanks to their strength and resistance to wear. When you choose woven materials, you get durability essential for protective clothing, gloves, and harnesses used in construction, manufacturing, and firefighting.

These fabrics provide reliable tear resistance and maintain integrity under stress, keeping you safe in hazardous environments. You’ll also find woven fabrics in industrial filters and conveyor belts, where consistent strength and dimensional stability matter.

Because the fibers interlace tightly, woven fabrics resist abrasion and provide a sturdy barrier against mechanical damage. Their versatility allows you to customize weight and weave patterns, tailoring gear to specific safety requirements.

Home Furnishings

Although home furnishings face different demands than industrial gear, their need for durability and aesthetic appeal is just as important.

When you choose woven fabrics for your home, you get a combination of strength and elegance that nonwovens can’t always provide. Woven fabrics hold up well under daily use, resist wear, and maintain their shape, making them ideal for various applications.

You’ll find woven fabrics commonly used in:

- Upholstery, where toughness and texture matter

- Curtains and drapes, offering both structure and style

- Decorative pillows, providing intricate patterns and durability

Typical Applications of Nonwoven Fabrics

Nonwoven fabrics offer remarkable versatility, making them a popular choice across many industries. When you use nonwovens, you benefit from their lightweight nature and cost-effectiveness.

In healthcare, you’ll find them in surgical gowns, masks, and wound dressings, where hygiene and disposability are essential. In automotive manufacturing, these fabrics serve as insulation, upholstery backing, and filtration materials, enhancing comfort and performance.

You can also see nonwovens in hygiene products like diapers and sanitary pads for their absorbency and softness. Additionally, the construction sector uses them for geotextiles and roofing materials due to their strength and durability.

Whether you’re tackling industrial, medical, or consumer needs, nonwoven fabrics deliver tailored solutions without compromising on function or efficiency.

Environmental Impact and Sustainability Considerations

You’ll want to contemplate where the materials come from when comparing woven and nonwoven fabrics, especially if eco-friendly sources matter to you.

Think about how each fabric breaks down or if it can be recycled to reduce waste.

Understanding these factors helps you make smarter, more sustainable choices.

Eco-friendly Material Sources

When choosing fabric, reflecting on eco-friendly material sources can greatly reduce your environmental footprint.

Both woven and nonwoven fabrics can be made from sustainable inputs, but your choice impacts resource use and waste generation. Opting for materials that minimize chemical treatments and rely on renewable resources benefits the planet.

Here are three key eco-friendly sources to reflect on:

- Organic fibers like organic cotton or hemp, grown without harmful pesticides

- Recycled materials such as recycled polyester or reclaimed natural fibers, reducing landfill waste

- Bio-based fibers derived from renewable crops like bamboo or lyocell, which use less water and energy

Biodegradability and Recycling

Although fabric choice influences many factors, understanding biodegradability and recycling is key to minimizing environmental harm.

When you choose woven fabrics made from natural fibers like cotton or wool, you’re opting for materials that biodegrade relatively quickly. These fabrics can also be recycled, though the process may require separating blended fibers.

Nonwoven fabrics often consist of synthetic polymers, which don’t break down easily and contribute to landfill buildup. However, some nonwovens use biodegradable materials or are designed for single-use applications with recycling in mind.

If you prioritize sustainability, check the fiber content and recycling guidelines. By doing so, you help reduce waste and promote a circular textile economy, making your fabric choice more responsible and eco-friendly.

Frequently Asked Questions

How Do Woven and Nonwoven Fabrics Differ in Cost Efficiency?

You’ll find nonwoven fabrics are generally more cost-efficient since they require less labor and time to produce. Woven fabrics, while durable, often cost more due to intricate weaving processes and higher material expenses.

What Are the Maintenance Requirements for Woven vs. Nonwoven Fabrics?

Think of woven fabrics as well-tended gardens; you’ll need regular washing and gentle care to keep them vibrant. Nonwoven fabrics are like wildflowers—easygoing but less durable, requiring minimal upkeep but careful handling to avoid damage.

How Do Woven and Nonwoven Fabrics Perform in Extreme Weather Conditions?

You’ll find woven fabrics usually handle extreme weather better, offering durability and breathability. Nonwoven fabrics might degrade faster under harsh conditions but excel in water resistance. Choose based on your specific environmental needs.

What Are the Common Dyeing and Finishing Techniques for Each Fabric Type?

Imagine painting on a tight canvas—wovens soak up reactive and vat dyes, then get finishes like mercerizing to shine. For nonwovens, you’ll use pigment dyes and thermal bonding finishes, sealing colors like a secret treasure.

How Do Woven and Nonwoven Fabrics Affect Skin Sensitivity or Allergies?

You might find woven fabrics gentler on sensitive skin due to their breathability and smooth texture. Nonwoven fabrics can sometimes irritate allergies because of their rougher feel and chemical treatments used during production.